A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

In the world of power distribution, cable joints play a critical role in ensuring efficient, safe, and reliable connections between cables. Among the available technologies, heat shrink cable joints stand out for their robust performance, versatility, and cost-effectiveness. This blog explores the key aspects of heat shrink cable joints, from their construction and benefits to applications and installation processes, offering valuable insights for power industry professionals.

What Are Heat Shrink Cable Joints?

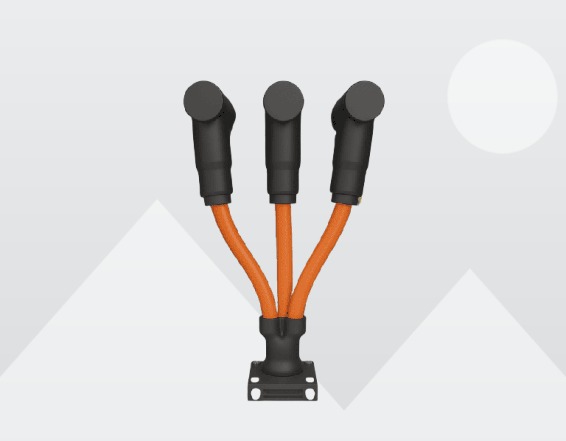

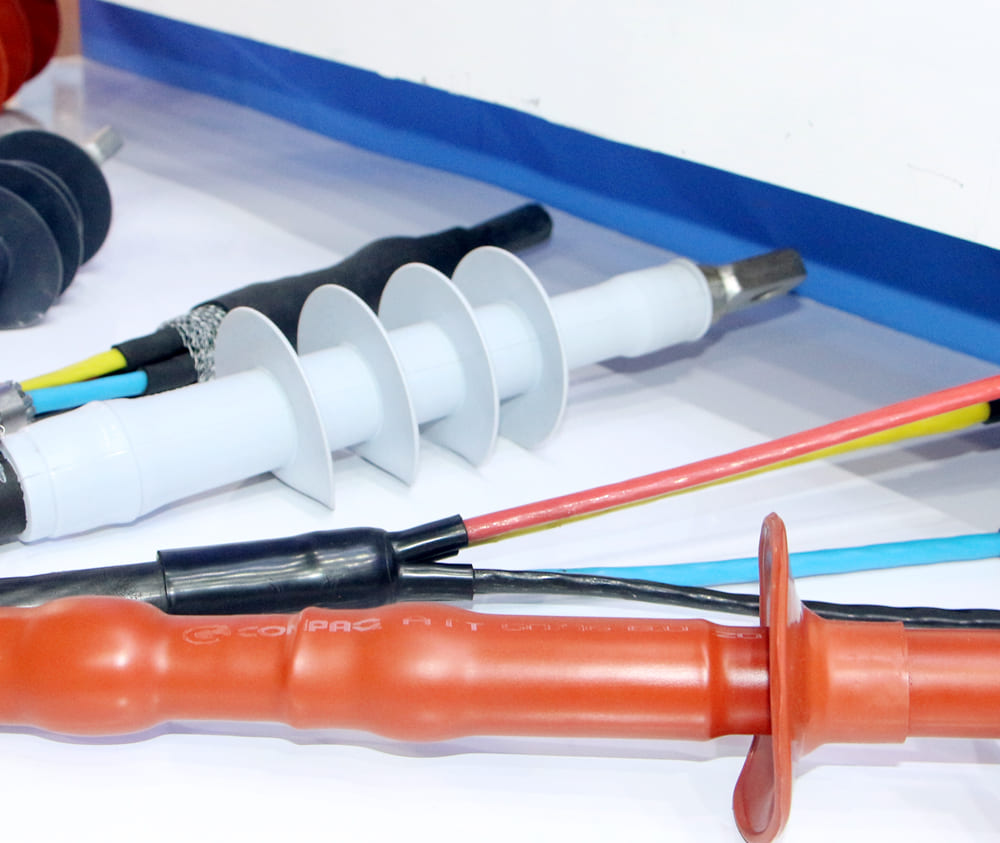

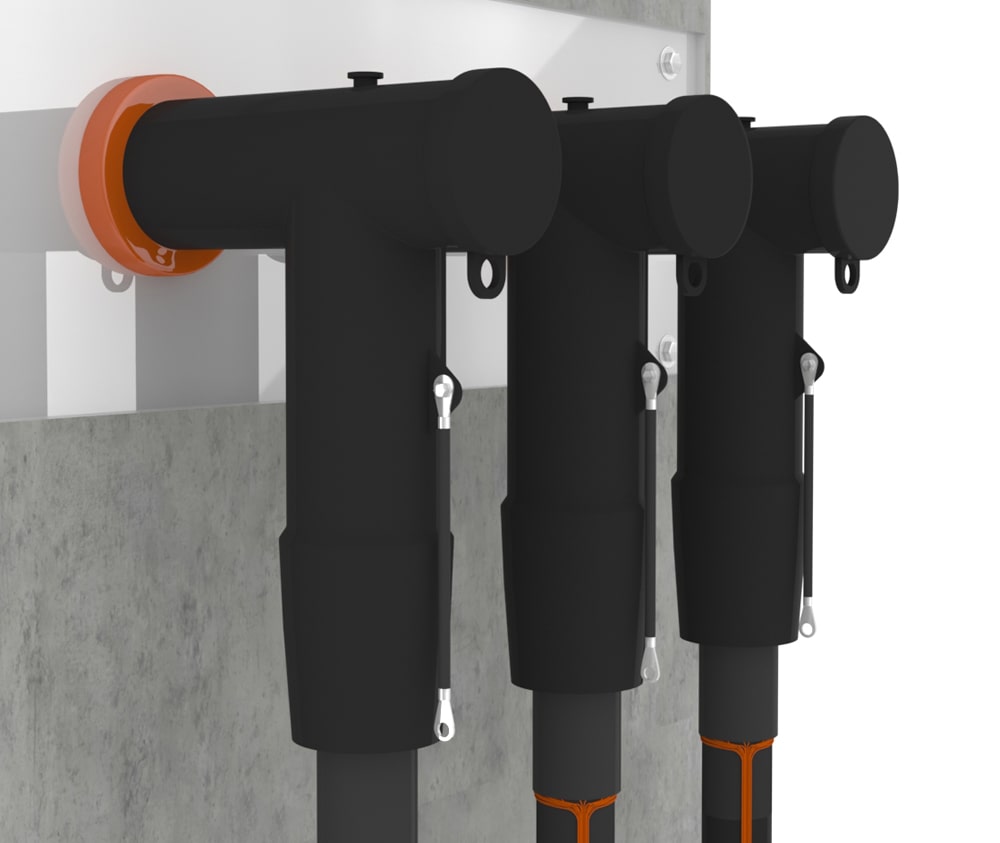

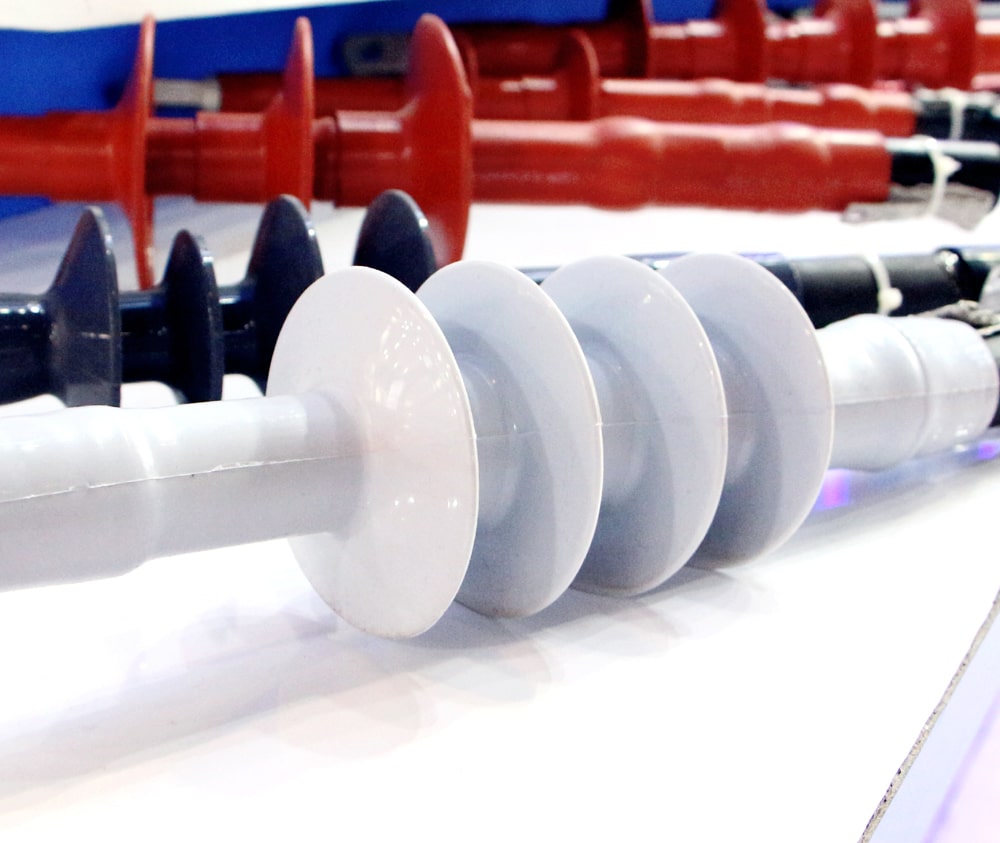

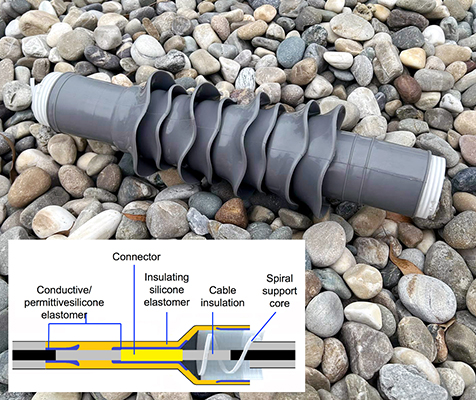

Heat shrink cable joints are advanced connection systems designed to provide insulation, mechanical protection, and environmental sealing for electrical cables. They consist of polymeric materials that shrink when heat is applied, tightly conforming to the underlying cable and ensuring a secure, watertight seal.

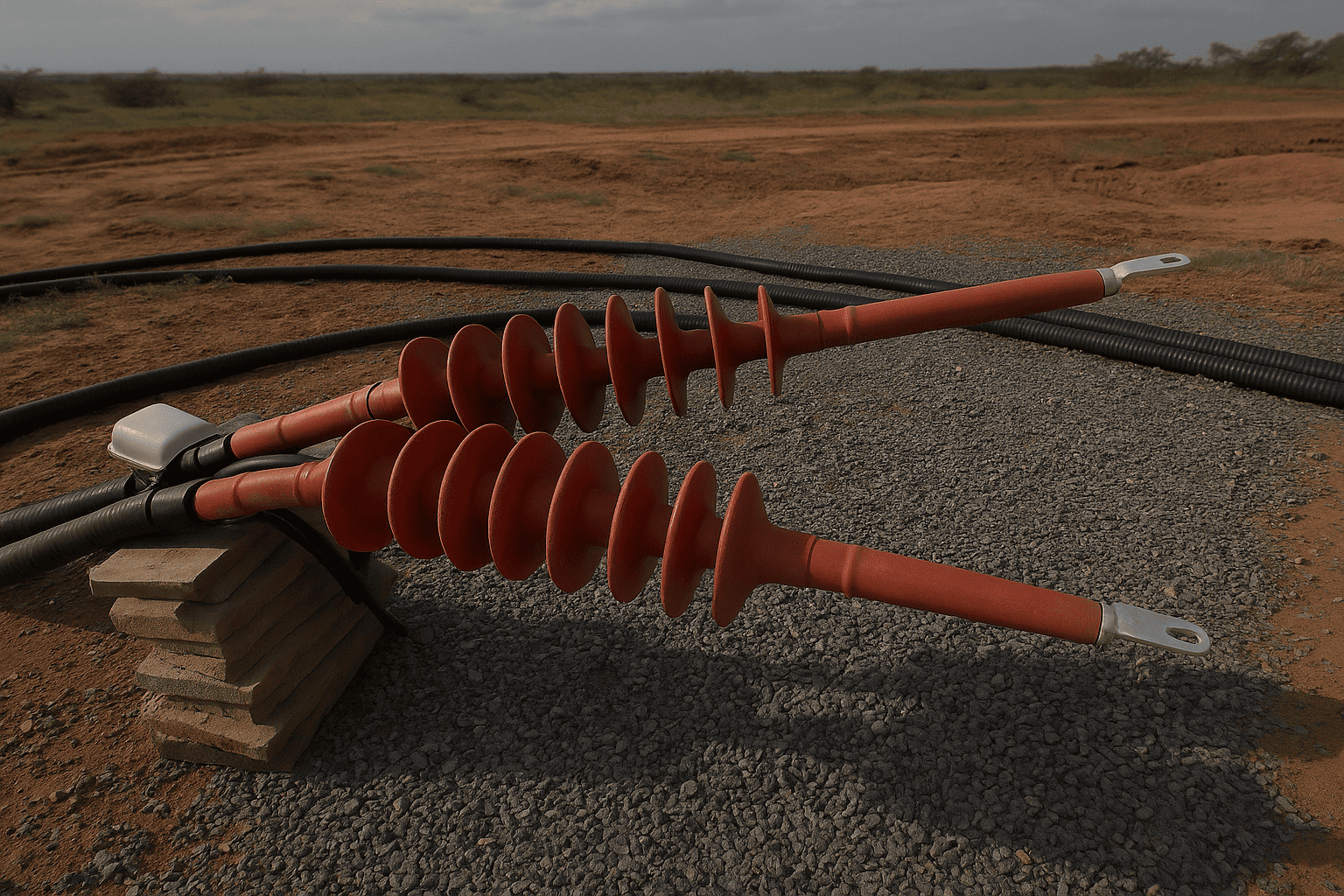

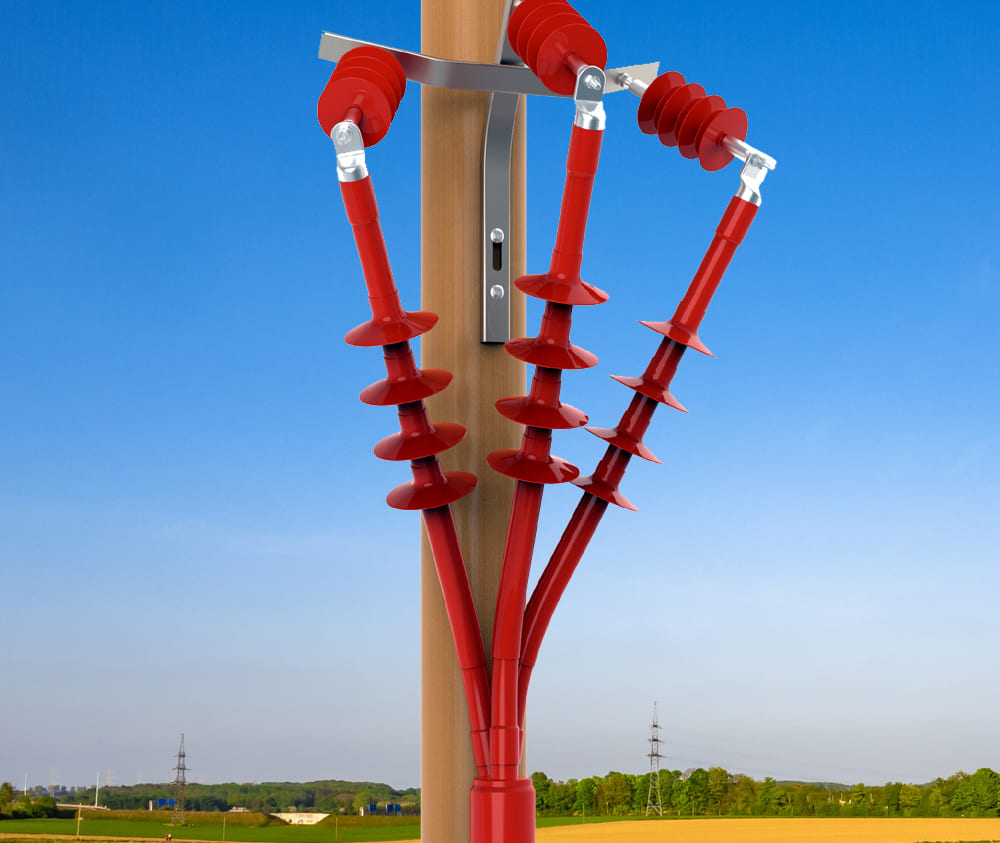

These joints are commonly used in low, medium, and high-voltage applications and are an ideal solution for connecting cables in underground, overhead, and industrial installations.

How Heat Shrink Cable Joints Work

- 1. Material Composition:

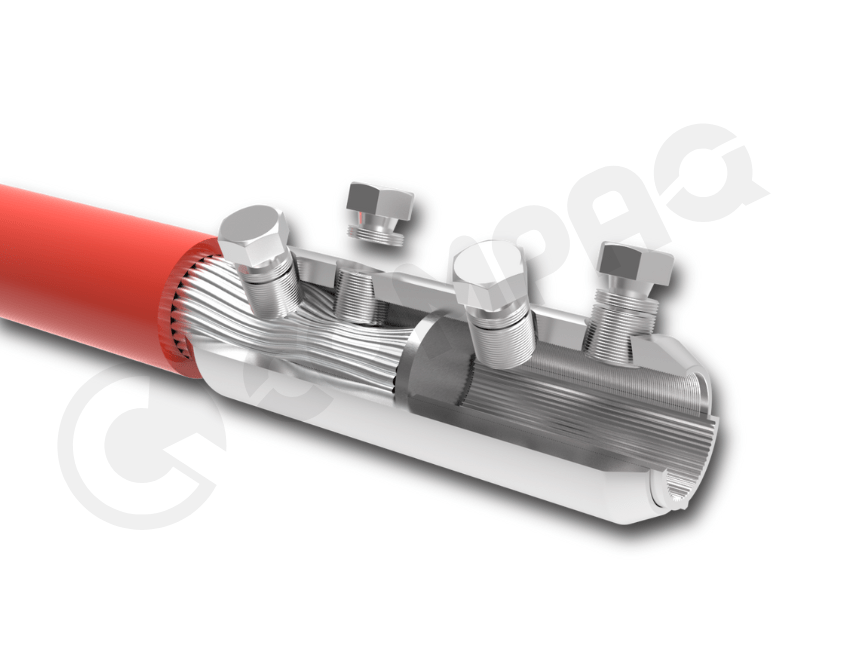

- Made from cross-linked polymer materials, typically polyethylene or polyolefin, which exhibit excellent heat shrink properties and high dielectric strength.

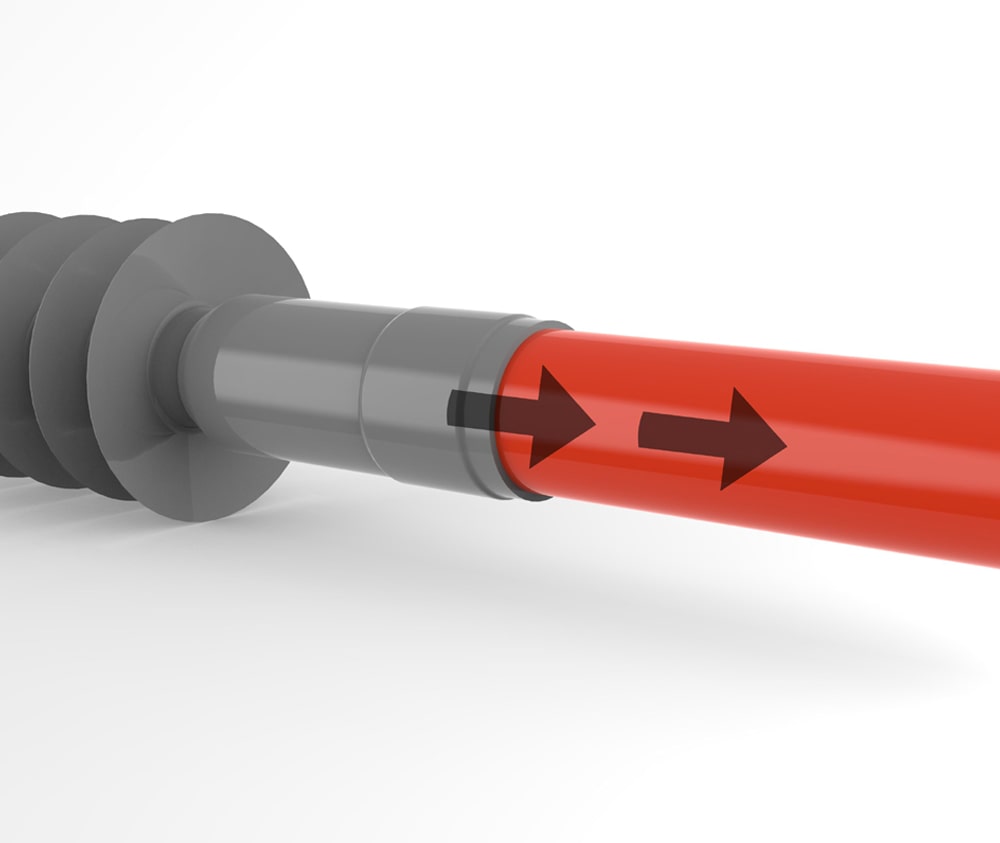

- 2. Shrink Mechanism:

- When exposed to heat, the pre-expanded heat shrink tubing contracts to its original size, tightly encasing the cable and providing a secure fit.

- 3. Built-in Protection:

- These joints often include stress control tubes, sealing mastic, and insulation layers to enhance performance and durability.

Key Features of Heat Shrink Cable Joints

- 1. Superior Insulation

- Provides excellent electrical insulation, ensuring reliable performance in high-voltage systems.

- 2. Environmental Sealing

- Protects against moisture, dust, and chemical exposure, making it ideal for harsh environments.

- 3. Mechanical Strength

- Enhances the durability of cable connections by resisting mechanical stress and vibration.

- 4. Versatility

- Suitable for a wide range of cable types, including XLPE, PILC, and EPR-insulated cables.

Benefits of Using Heat Shrink Cable Joints

- 1. Ease of Installation

- Lightweight and easy to transport.

- Requires basic tools and minimal expertise for installation.

- 2. Reliable and Long-Lasting

- Designed for decades of performance, reducing the need for frequent replacements.

- 3. Cost-Effective

- Offers a durable solution at a competitive price point, especially for large-scale installations.

- 4. Customizable for Specific Needs

- Available in various sizes and configurations to suit different voltage levels and cable diameters.

Applications of Heat Shrink Cable Joints

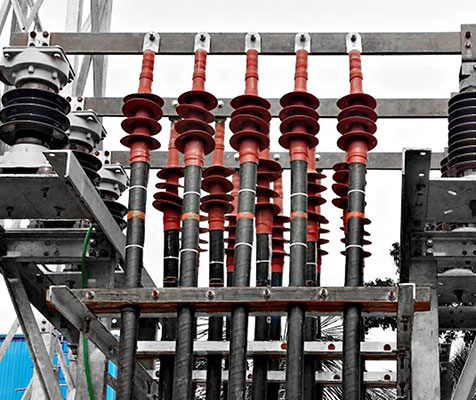

- 1. Power Utilities:

- Widely used for underground and overhead power transmission and distribution networks.

- 2. Renewable Energy:

- Ensures reliable cable connections in solar and wind power projects.

- 3. Industrial Installations:

- Provides durable connectivity for manufacturing plants, refineries, and other industrial setups.

- 4. Telecommunications:

- Protects signal-carrying cables from environmental factors, ensuring uninterrupted communication.

Installation Process of Heat Shrink Cable Joints

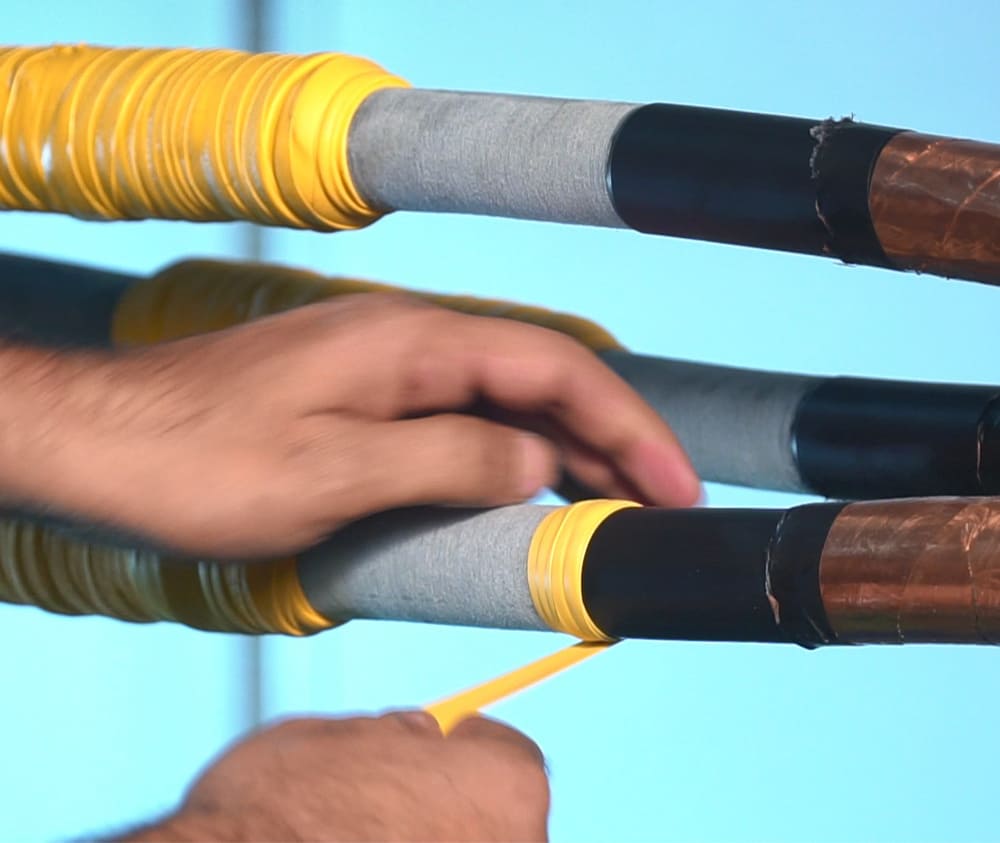

- 1. Cable Preparation:

- The cables to be joined are cleaned, stripped, and prepared according to the manufacturer’s guidelines.

- 2. Positioning the Joint:

- Heat shrink components, including stress control tubes and insulation layers, are positioned over the cable.

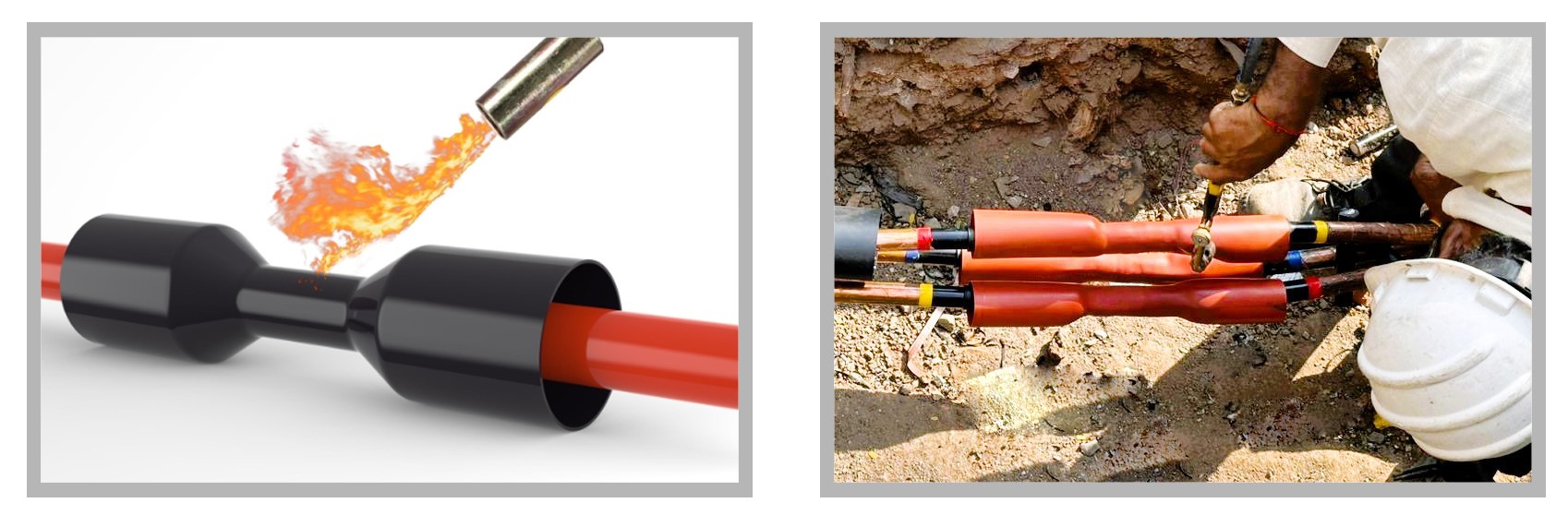

- 3. Application of Heat:

- A heat source (e.g., propane torch or heat gun) is used to shrink the tubing, ensuring it tightly conforms to the cable.

- 4. Sealing and Testing:

- The joint is sealed with adhesive or mastic layers and subjected to electrical testing for performance verification.

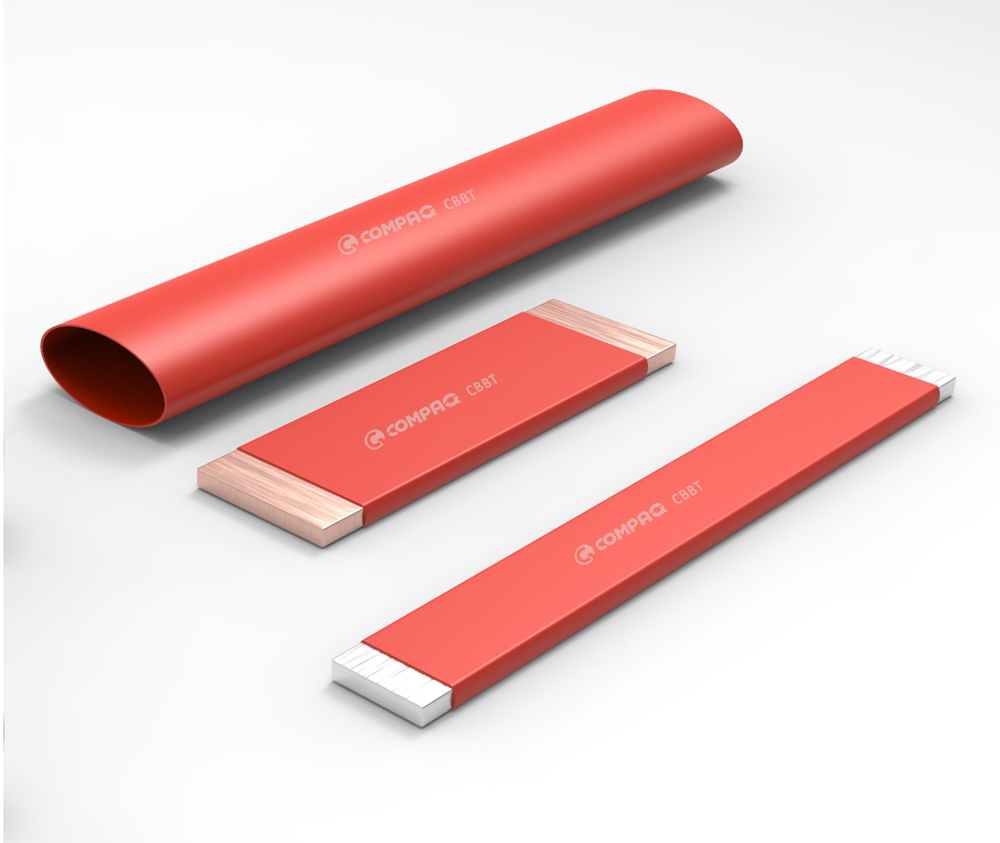

Why Choose Compaq’s Heat Shrink Cable Joints?

Compaq International offers a premium range of heat shrink cable joints, engineered for reliability and durability in the most demanding applications. Key highlights include:

- High-Quality Materials: Manufactured using cross-linked polymers for superior insulation and environmental resistance.

- Rigorous Testing: Complies with international standards like IEC and IEEE to ensure consistent performance.

- Versatile Solutions: Customizable designs for various voltage levels, cable types, and installation conditions.

- Expert Support: Installation training and technical guidance provided by Compaq’s experienced team.

Heat shrink cable joints are a trusted solution for reliable, long-lasting cable connections in diverse applications. Their ease of installation, combined with exceptional mechanical and electrical performance, makes them a preferred choice in power systems worldwide.

Explore Compaq International’s range of heat shrink cable joints to experience the perfect blend of innovation, quality, and performance for your cable connection needs.

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

What is Touch-Proof Terminations and why Utilities are Switching to it

What is Touch-Proof Terminations and why Utilities are Switching to it

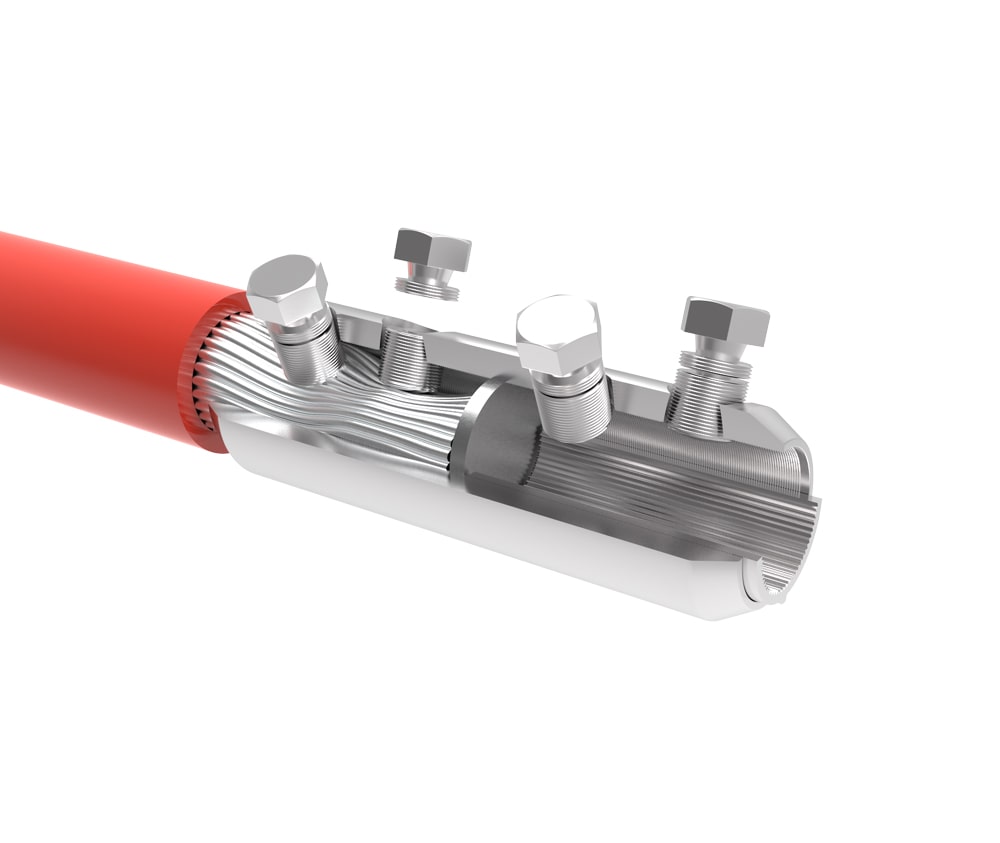

Mechanical Shear Head Cable Lugs & Connectors

Mechanical Shear Head Cable Lugs & Connectors

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?