What is Cold Shrink Technology and What is it Used for?

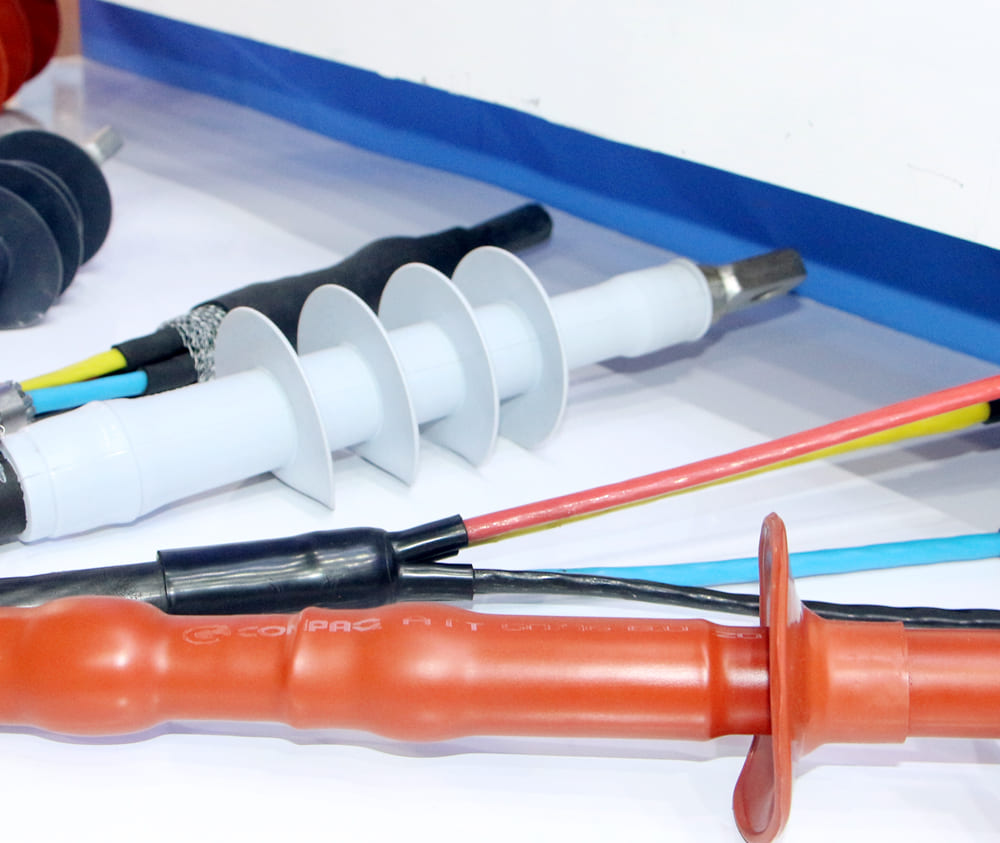

Cold shrink has emerged as a convenient technique for making connections between a cable and another cable, the terminal of an equipment or the terminal of an electrical junction. Electrical installers often utilize this technology to provide a tightly fitted, protective seal around stranded and solid wire conductors as it is safe and easy to use.

Traditionally, cable jointing was done with heat shrink technology which involved applying heat to artificially expanded plastic tubes. Upon the application of heat, these plastic tubes shrunk to provide electrical insulation or jointing cables. However, heat shrink technology could not be utilized safely in all kinds of environments. For example, it was quite risky to use heat-producing tools in areas with flammable gasses, such as gas pipeline projects. Cold shrinking was developing as a safer alternative for terminating & jointing in areas with such issues.

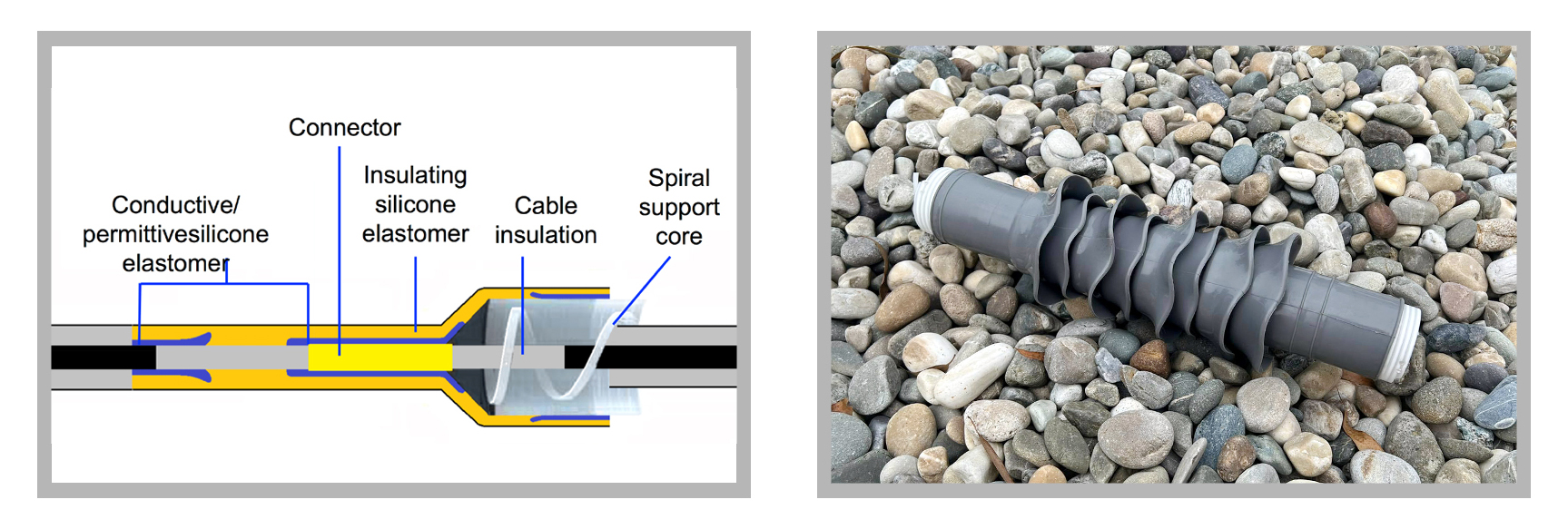

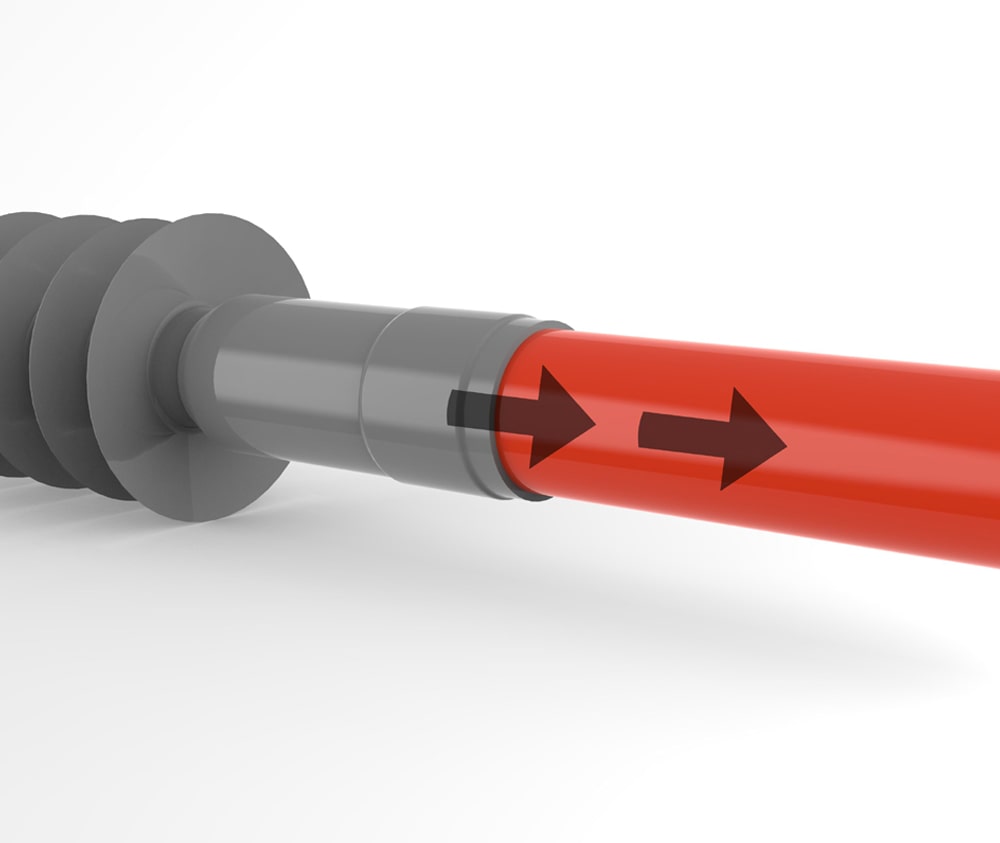

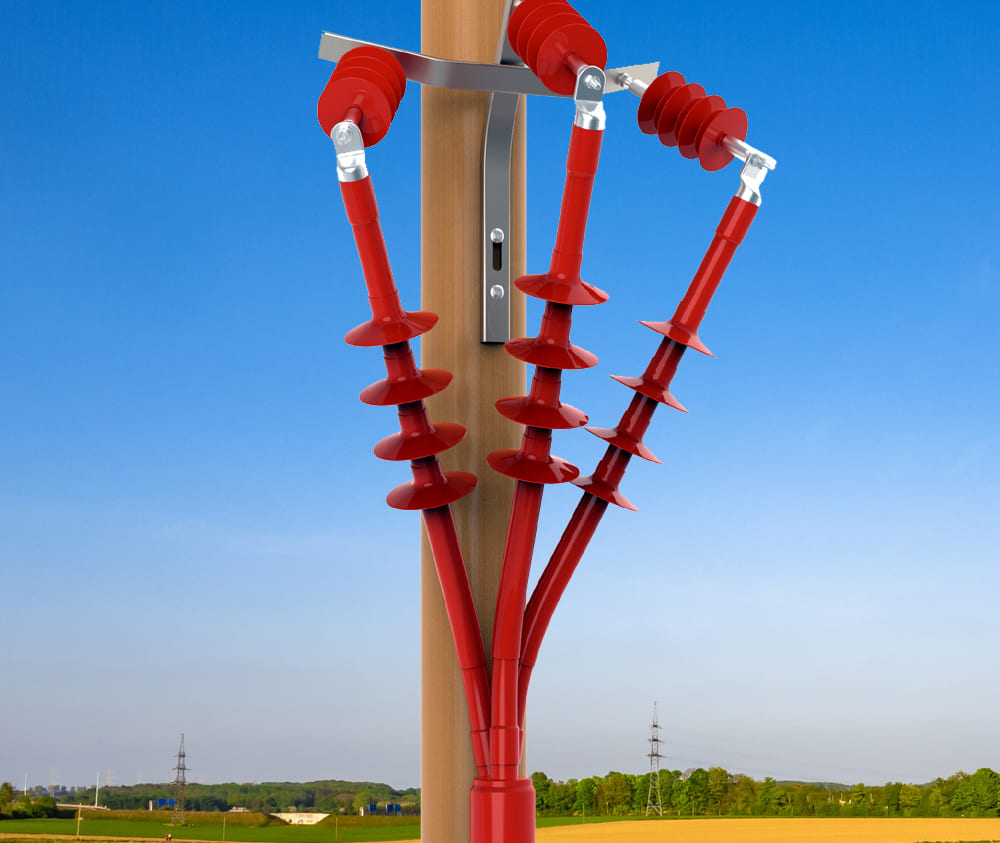

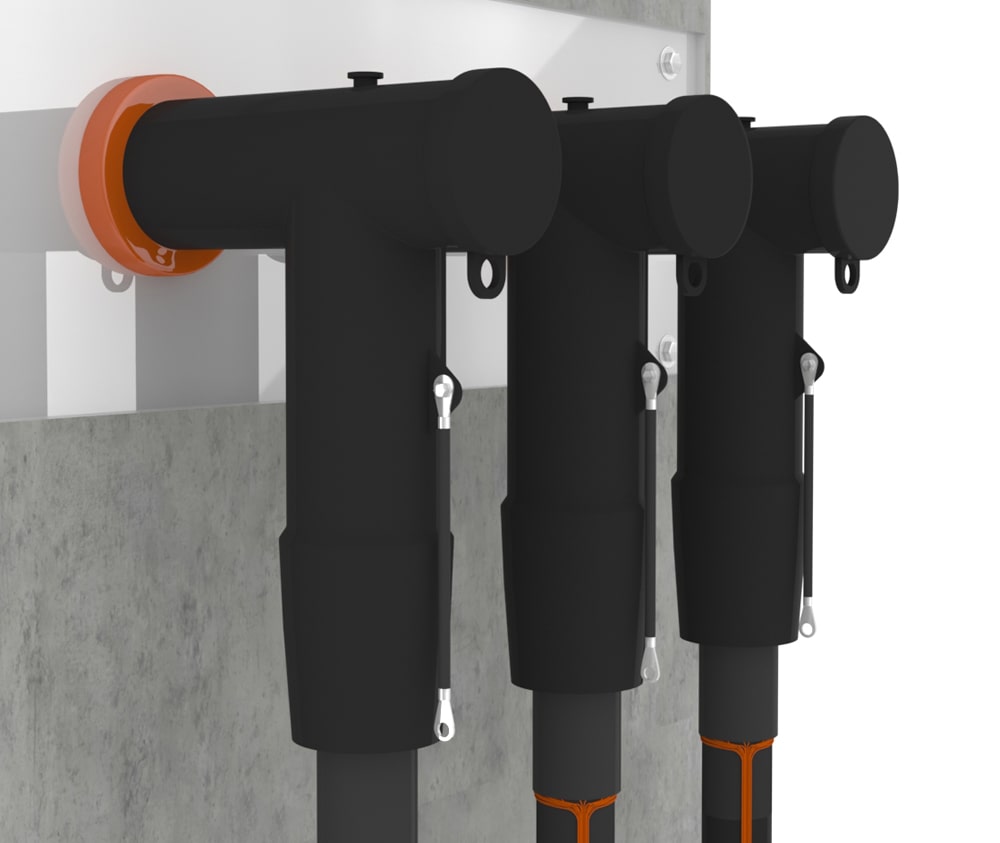

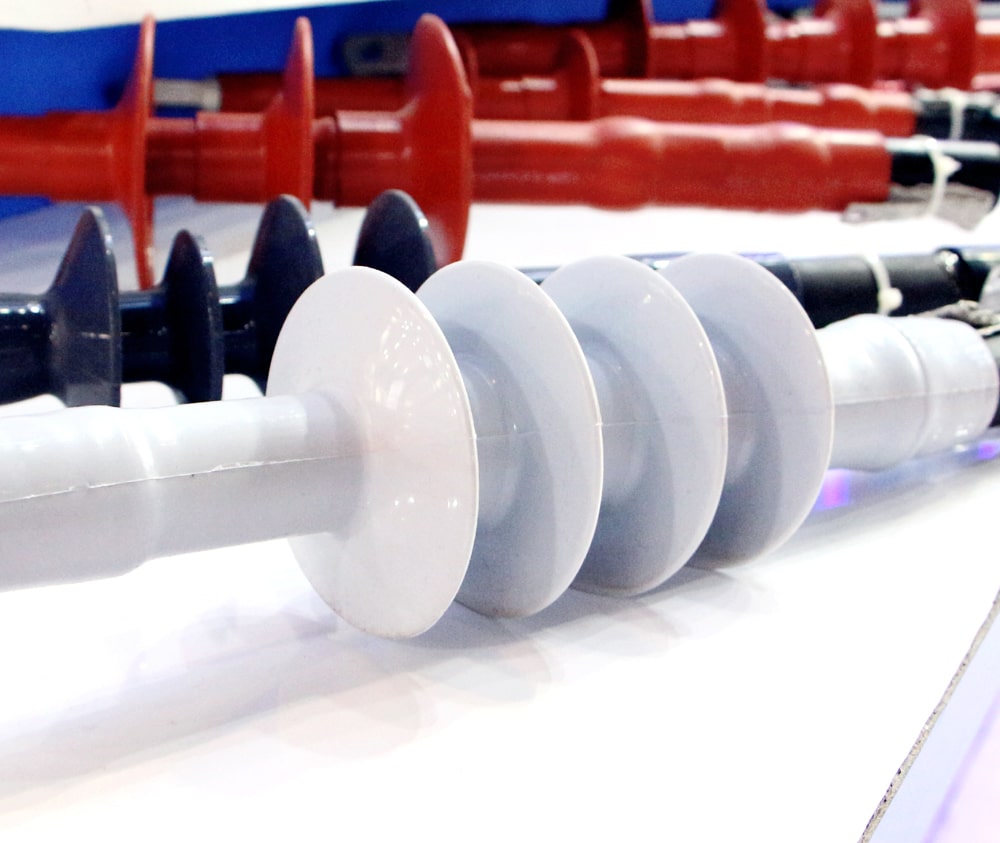

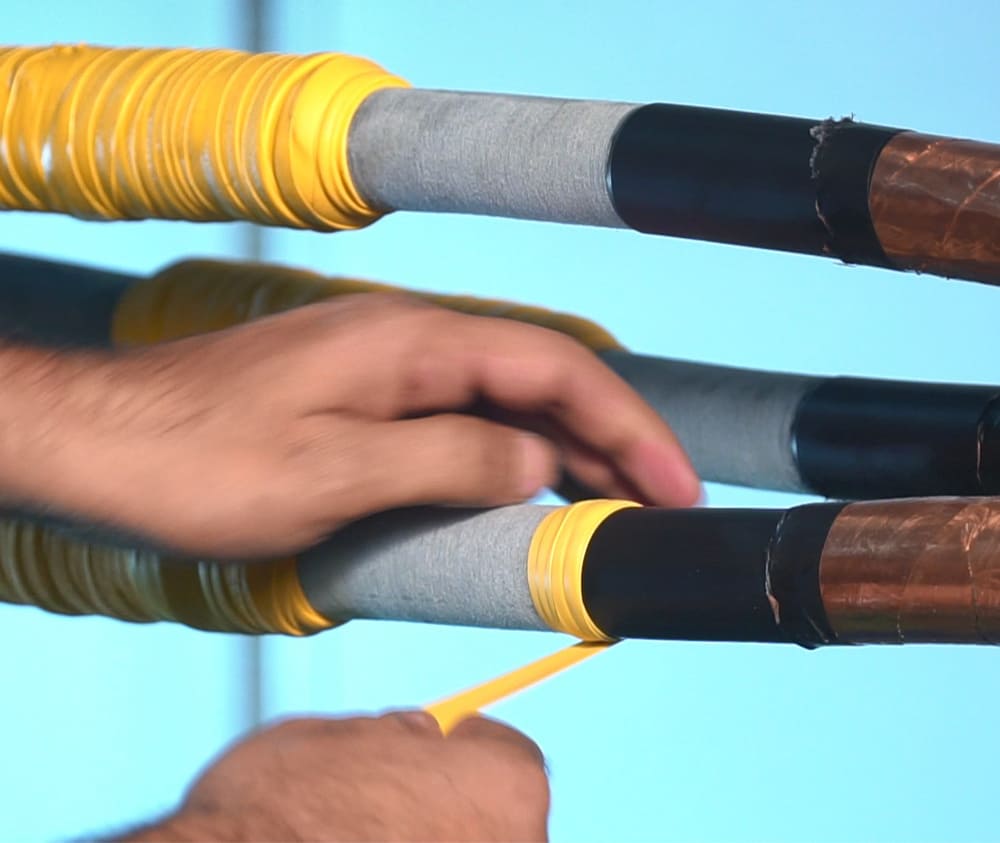

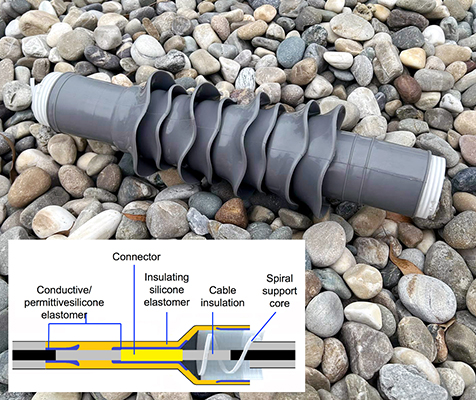

In cold shrink technology, accessories such as joint body, terminal body and tubes are made with materials such as rubbers and silicones that offer a high level of elasticity at ambient temperatures and are excellent at connecting and sealing power cables. The cold shrink tubes have a removable inner support system, which, when pulled out, causes the tube to shrink to its pre-stretched size. The tube wraps the cable perfectly and constantly exerts radial pressure for the lifetime of the joint or termination.

For correct utilization of cold shrink tubes, technician must only remove the inner core during the installation stage and not before. The cold shrink tubes must remain in their expanded state before they are actually being used for installation.

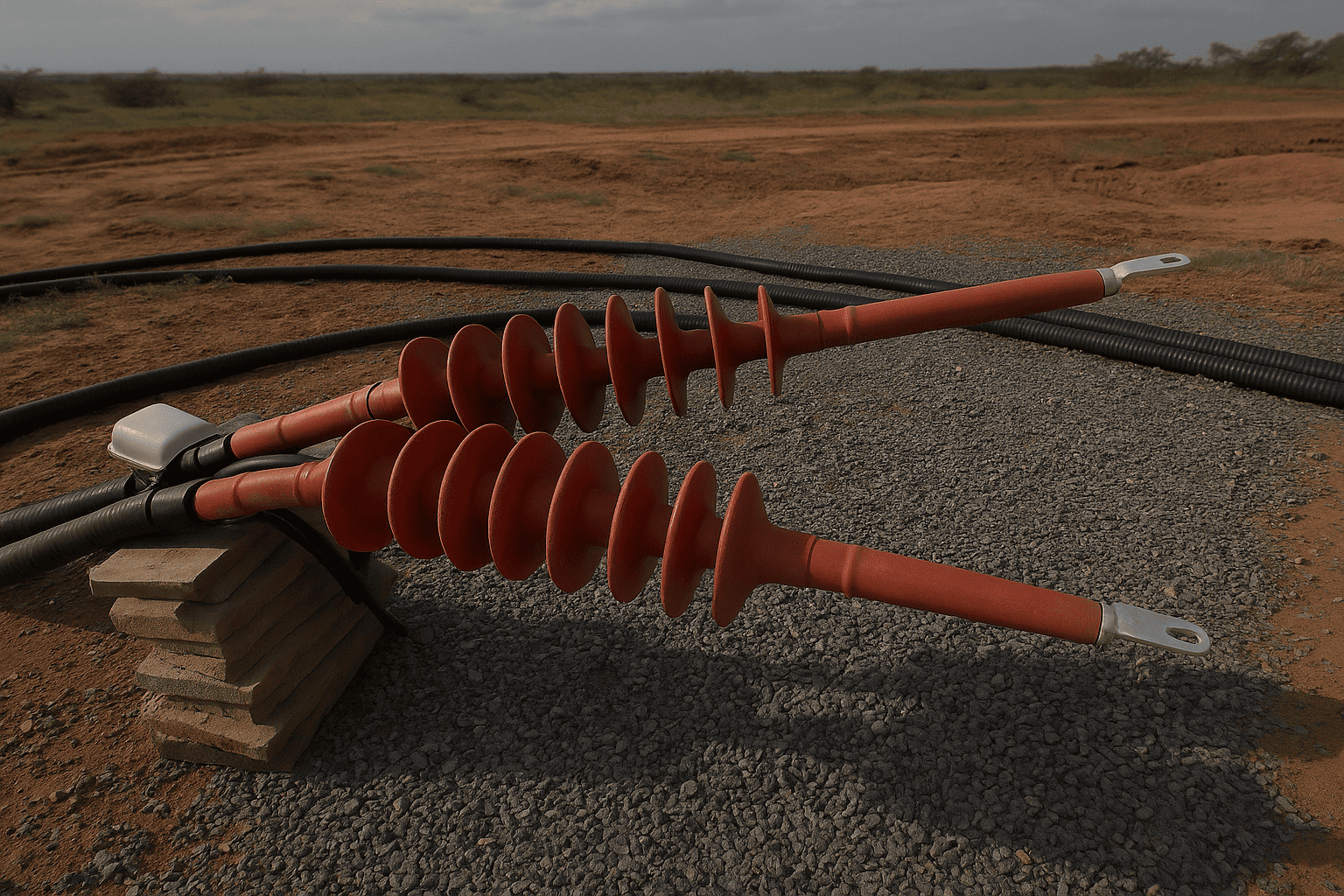

Cold shrink technology is optimized for field use and can withstand environmental conditions such as UV, pollution and chemicals, and salt fog. It can be utilized easily in onshore, offshore, indoor and outdoor environments. Furthermore, it is more suitable than heat shrink technology in places with space constraints where electrical tools and equipment cannot be used easily. Owing to these excellent practical features, cold shrink technology is experiencing widespread adoption in the electrical industry.

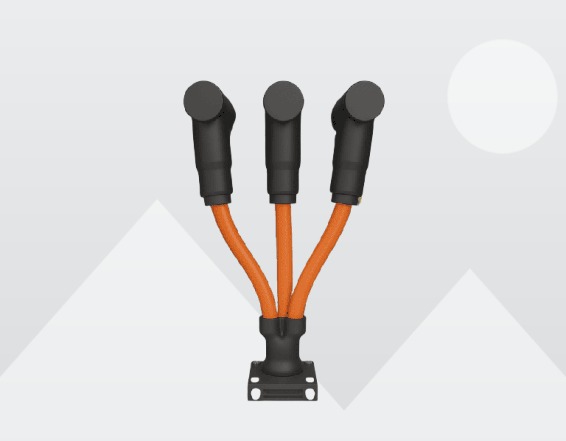

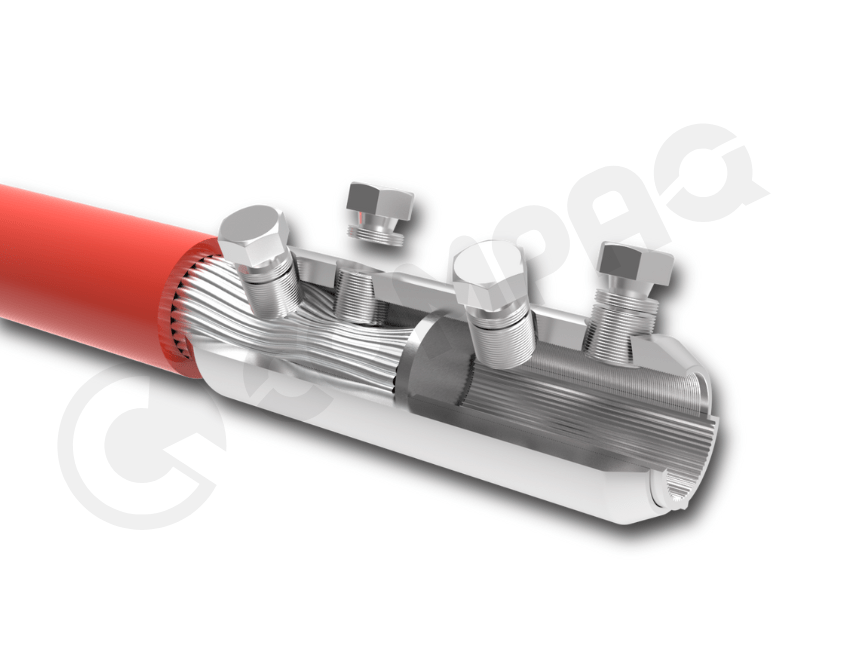

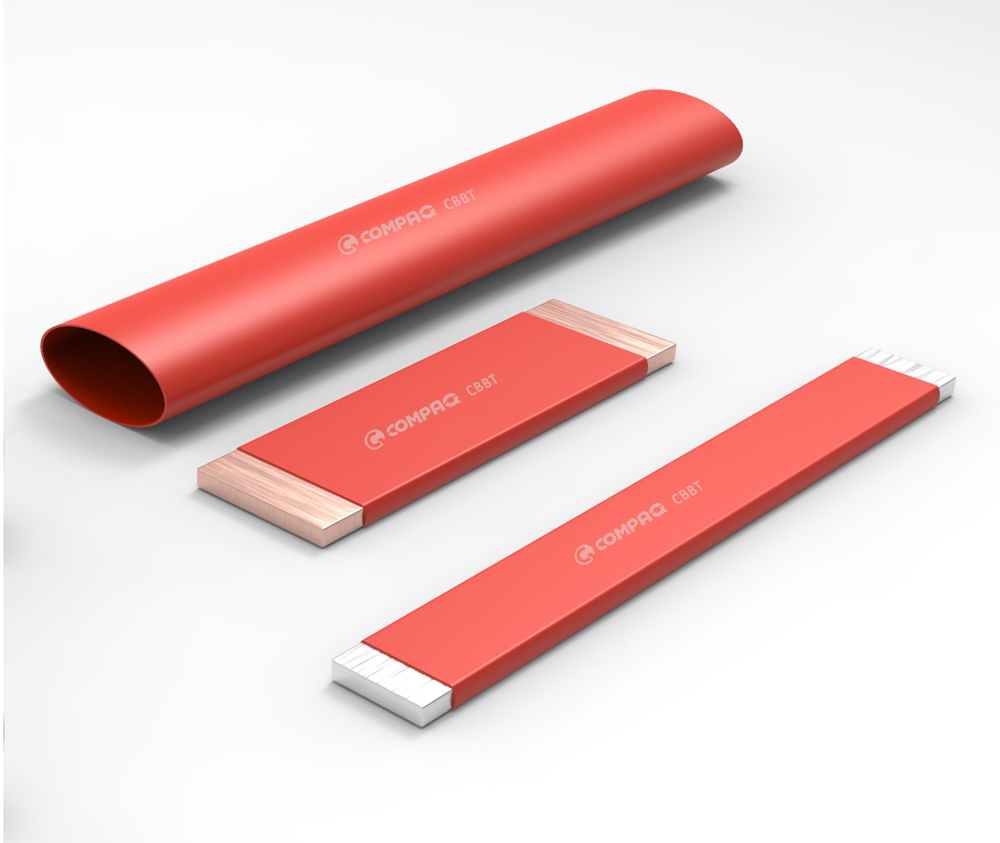

Compaq International is among the leading manufacturers of cold shrink products in not just India, but globally. Its product offerings include Cold Shrink Cable Joints, Cable Terminations, Flexible Bushing Boots, Trifurcation Kit for 3 Core MV Cables, Silicone Rubber Cold Shrink Tubing, EPDM Cold Shrink Tubing, Breakout Boots and End Caps. All of Compaq International’s products are made with only top quality raw materials and tested thoroughly for quality at each step of manufacturing.

To inquire about our cable accessories, call us on +918683961010 or write to us at [email protected].

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

What is Touch-Proof Terminations and why Utilities are Switching to it

What is Touch-Proof Terminations and why Utilities are Switching to it

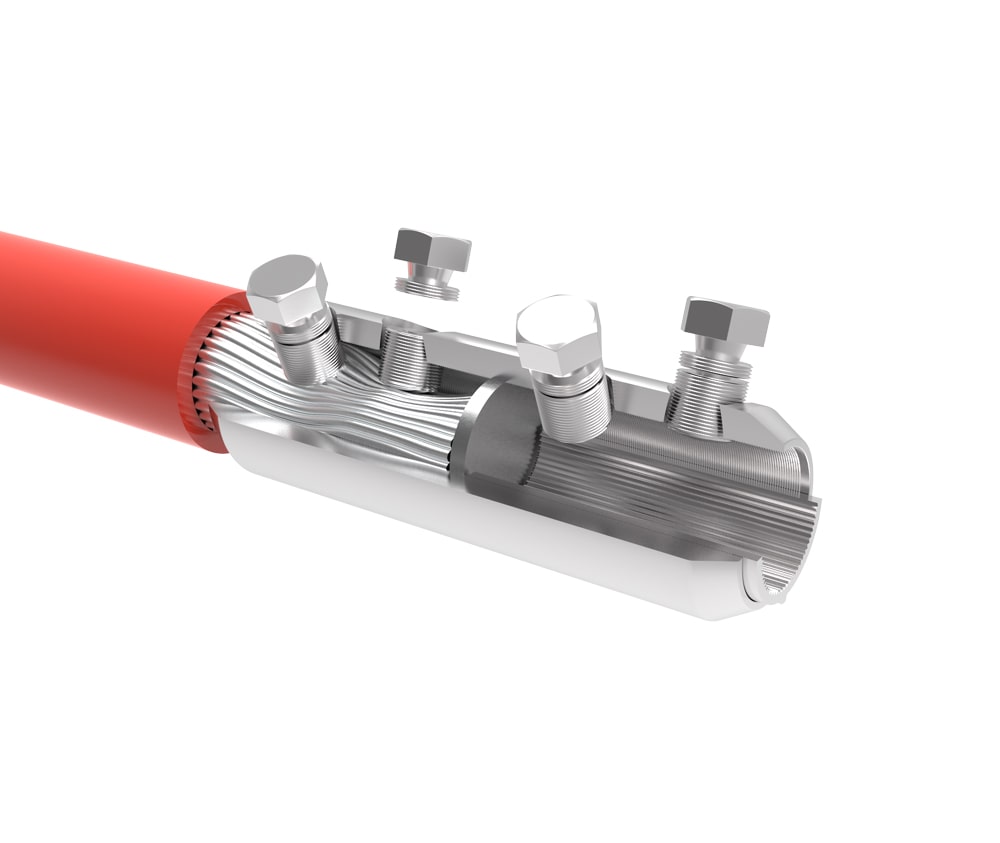

Mechanical Shear Head Cable Lugs & Connectors

Mechanical Shear Head Cable Lugs & Connectors

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?