How to Reduce Cable Joint Failure and Build a Reliable Network?

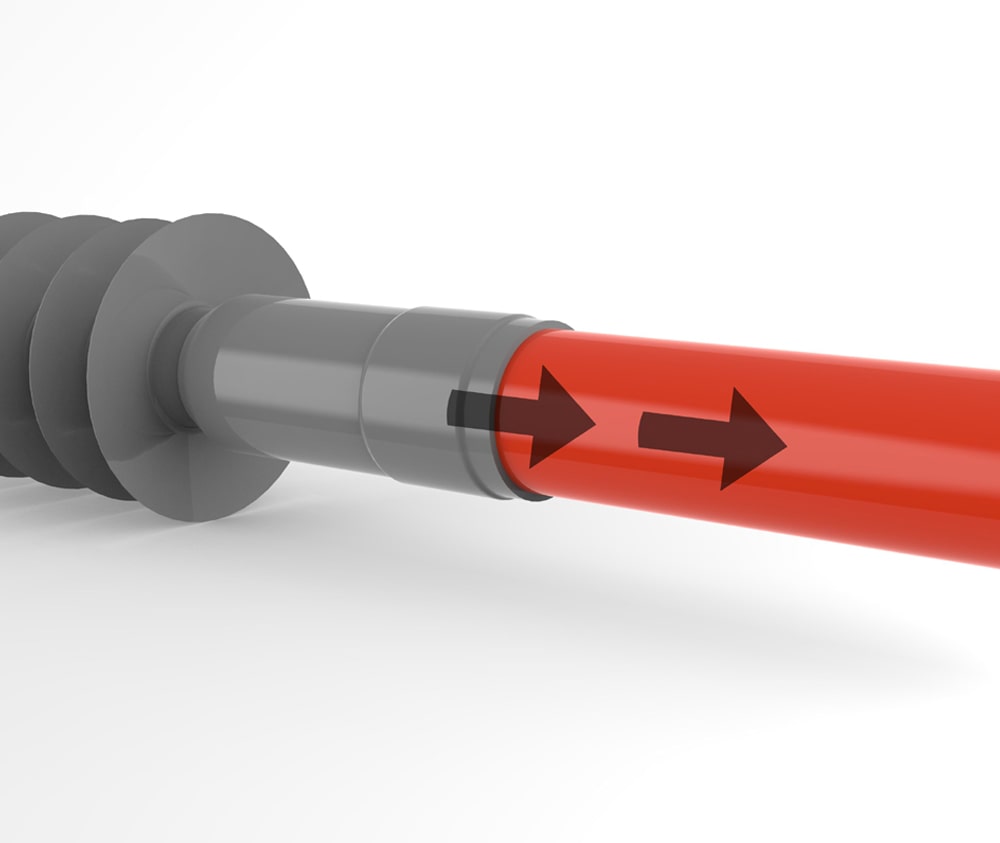

Cables are an integral part of any network, and cable joints are used to connect two or more cables. The joints are designed to provide a secure and reliable connection between cables. However, cable joint failure can cause a range of problems, including network downtime and loss of productivity. Cable joint failure can be caused by a variety of factors, including improper installation, environmental factors, and wear and tear over time. In this blog, we will discuss some steps that can help in reducing cable joint failure and building a reliable network.

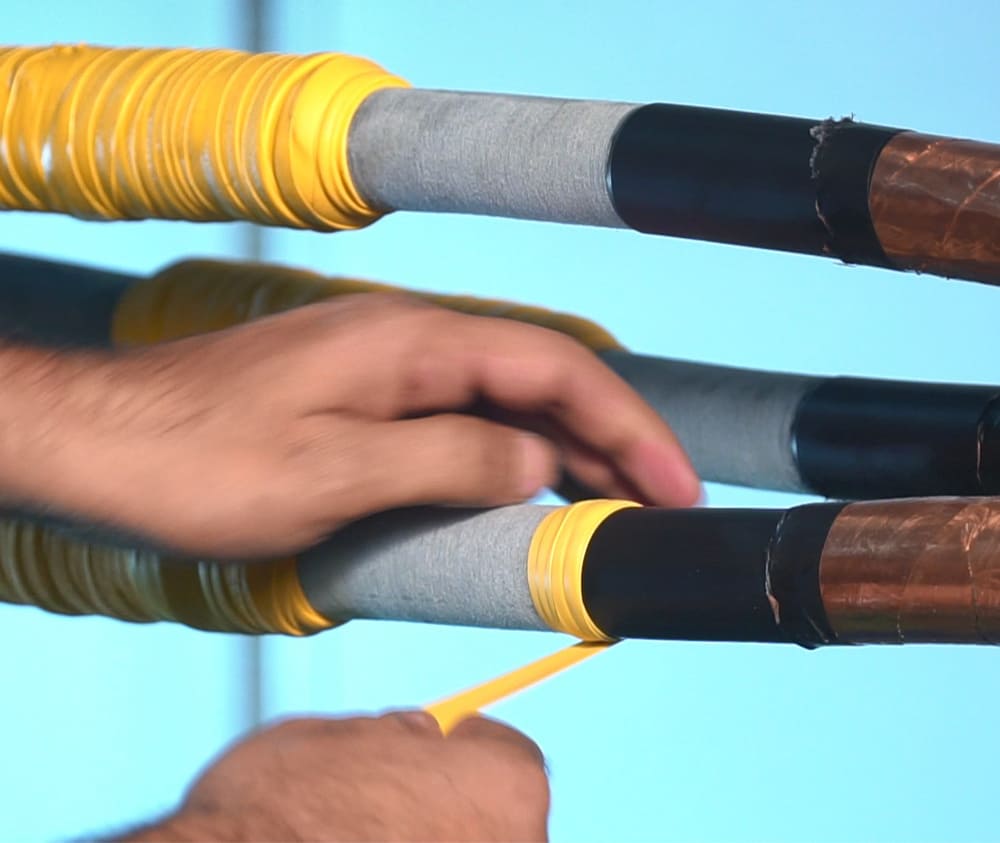

1. Proper Installation and Workmanship

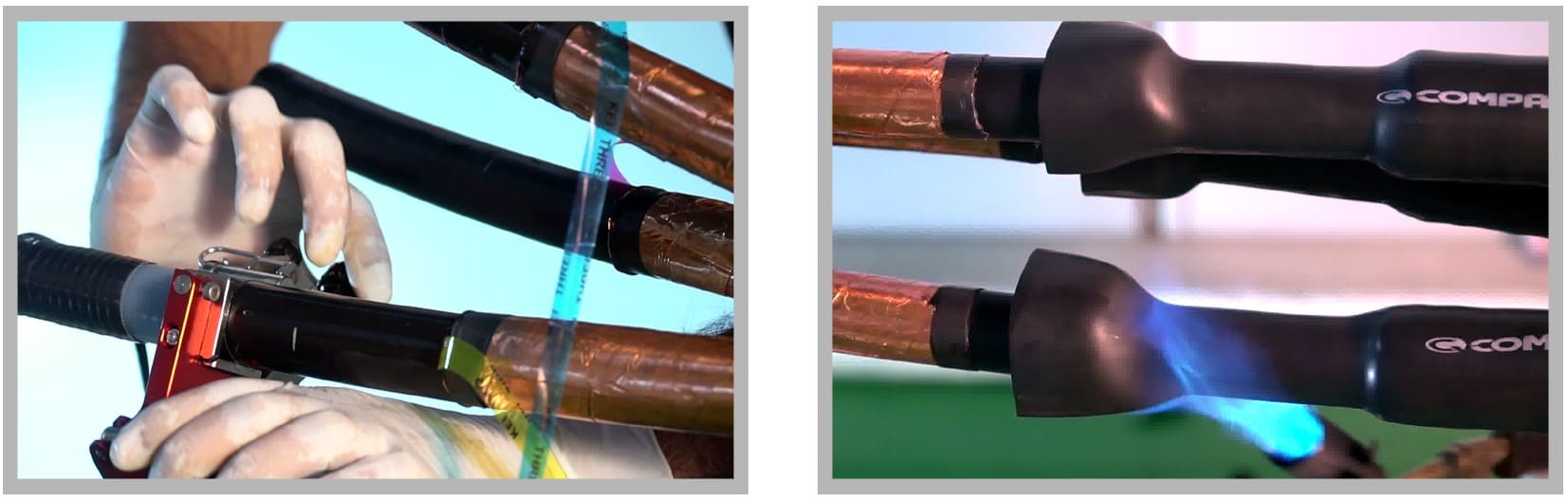

The first step in reducing cable joint failure is to ensure that the cable joints are installed properly according to the manufacturer's specifications and industry standards. It is crucial to use the correct tools, techniques, and materials during installation. The technicians involved in the installation should have the necessary training and experience to install the joints correctly.

2. Regular Maintenance

Cable joints need to be inspected regularly for signs of wear and tear, damage, or corrosion. Regular maintenance can help in identifying potential issues and resolving them before they become a significant problem. The damaged or worn-out parts should be replaced promptly to prevent any further damage.

3. Environmental Factors

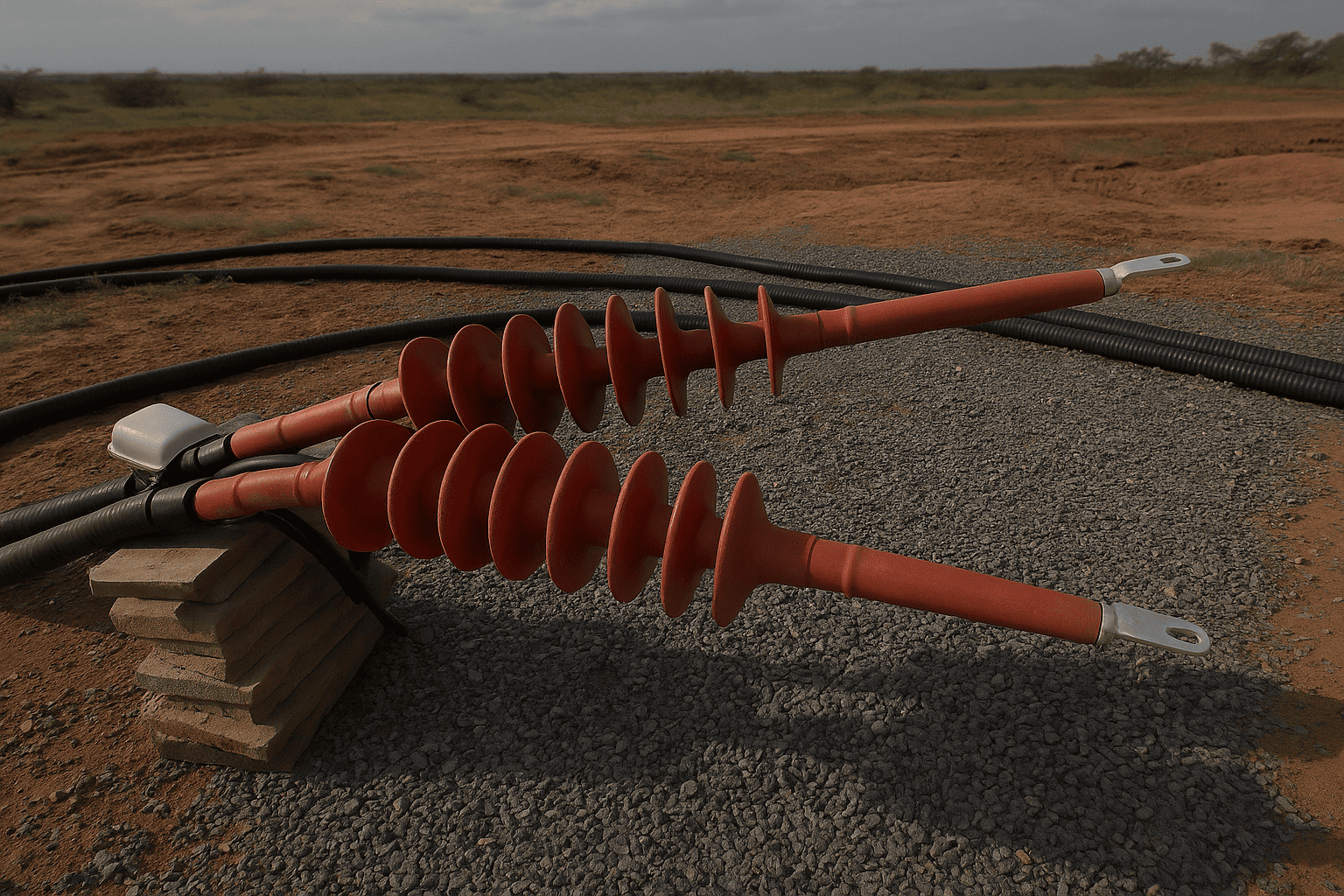

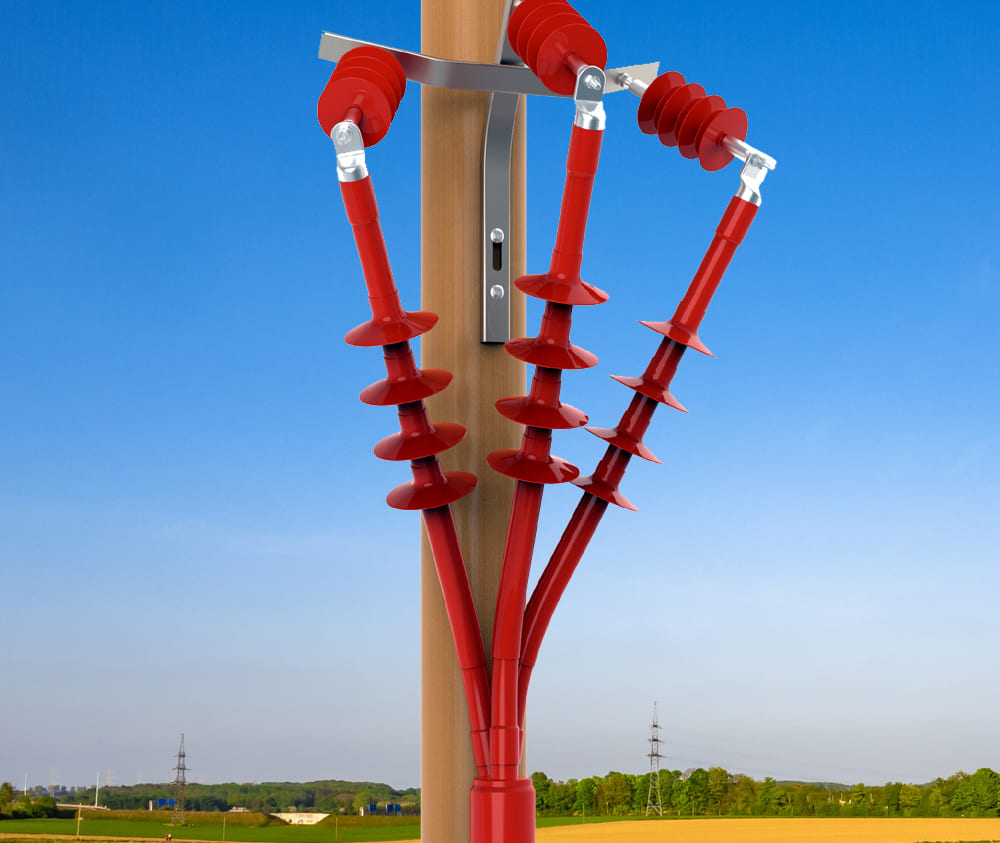

Environmental factors can play a significant role in the performance of cable joints. Factors such as temperature, humidity, and exposure to chemical or moisture can affect the performance of joints. It is essential to consider the environment in which the cable joint will be installed and choose material and installation methods that are suitable for that environment.

4. Quality Products

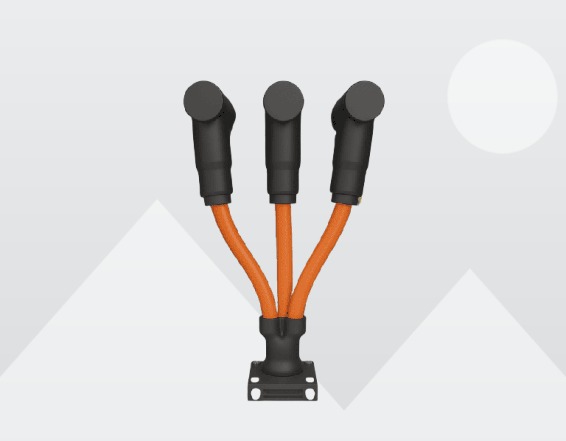

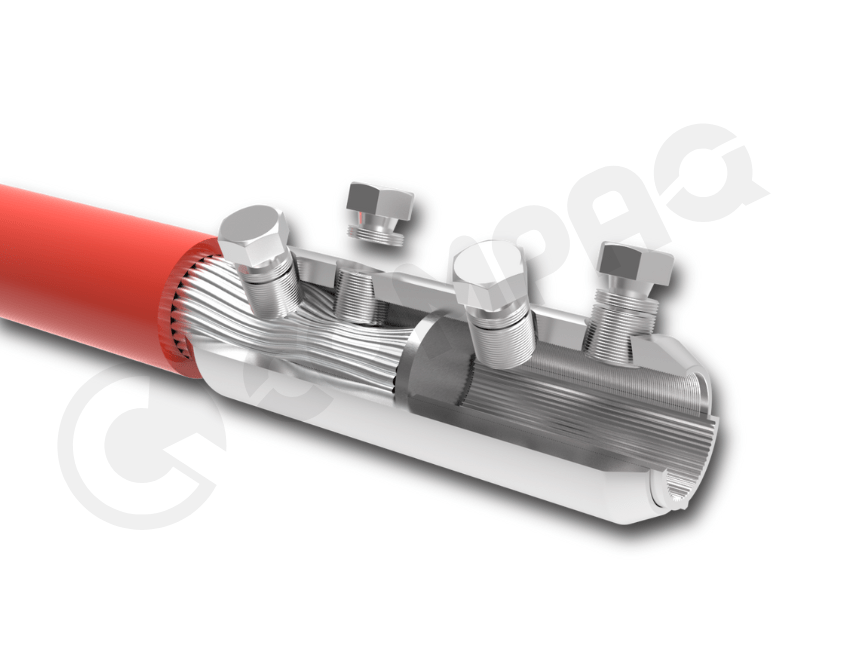

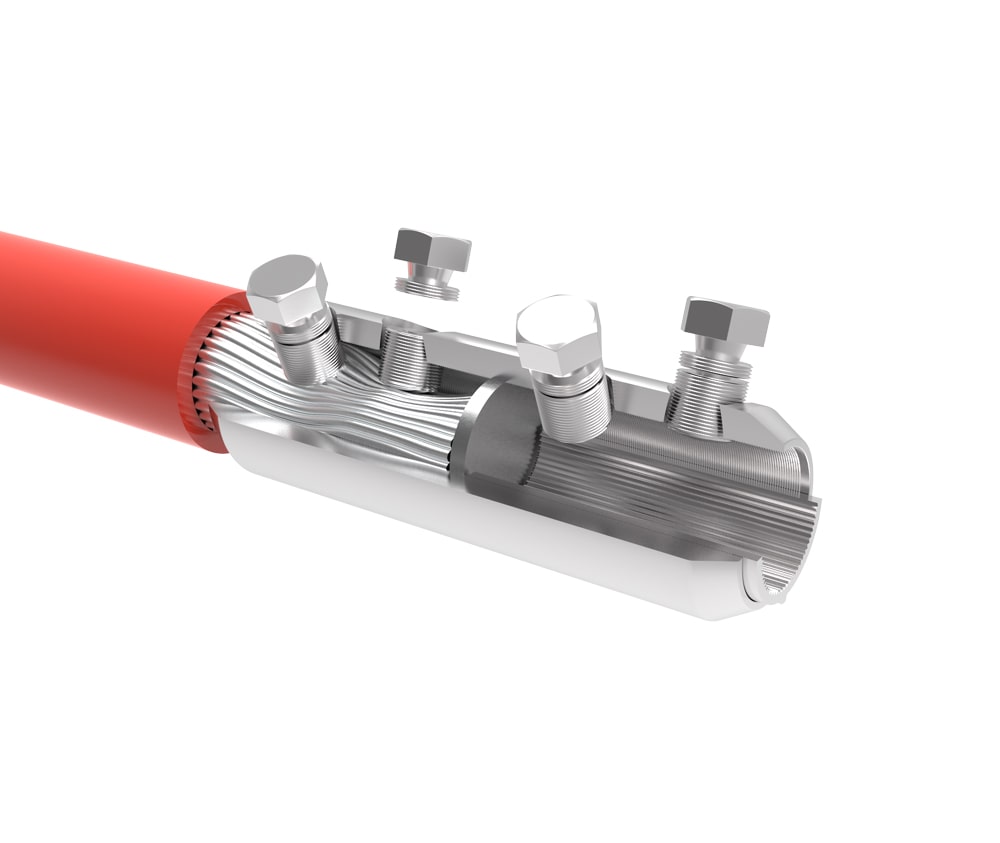

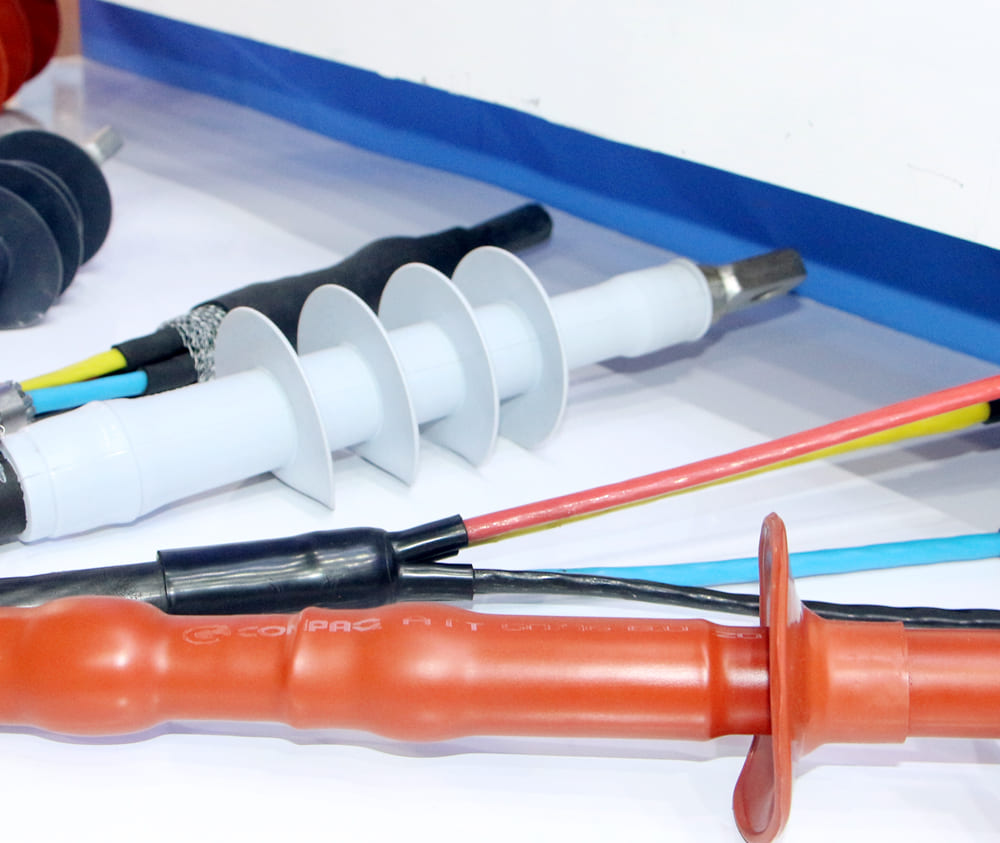

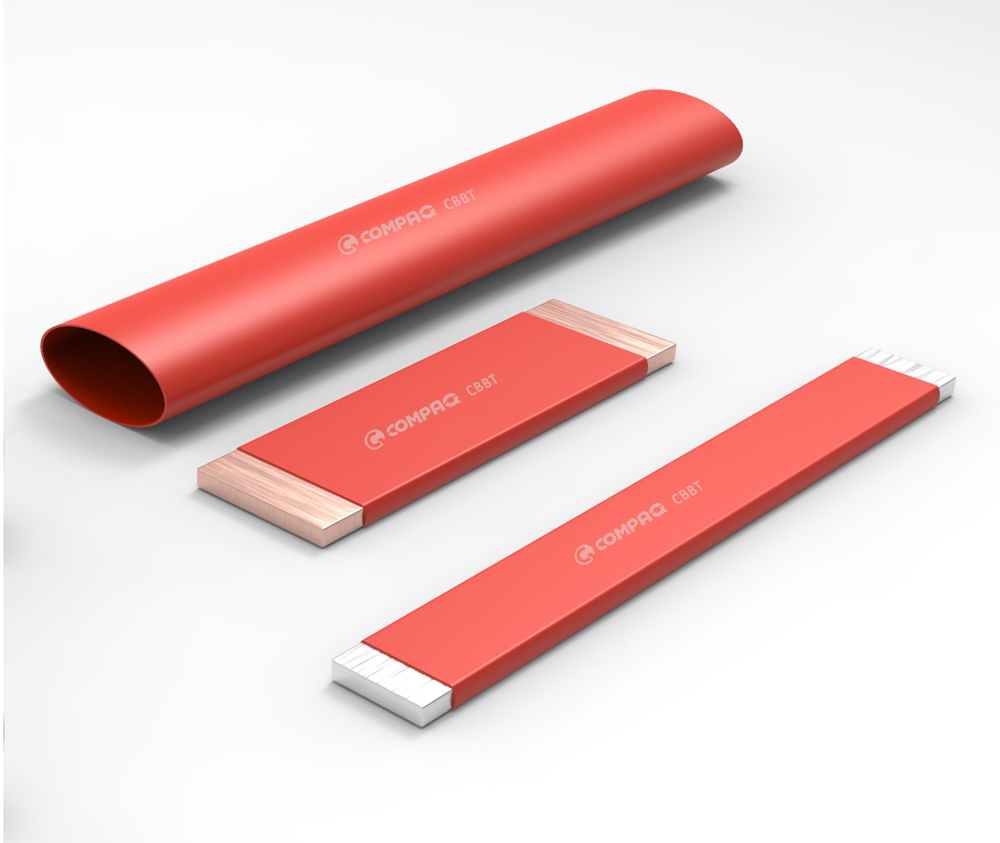

The quality of the cable joint product is another critical factor that can affect its performance. It is recommended to use high-quality cable joint products from reputable manufacturers such as Compaq International. Using cheap or substandard products may not meet industry standards and can lead to joint failure.

5. Testing

Testing the cable joints before and after installation is essential to ensure that they are properly installed and functioning correctly. The technicians should use appropriate testing equipment and follow industry standards during testing.

6. Proper Documentation

Maintaining proper documentation of cable joint installations, maintenance, and testing is essential. This information can help in identifying potential issues and prevent future failure. The documentation should include information such as the installation date, manufacturer and model number of the joint, and the technician who installed it.

Proper planning, installation, maintenance, and testing are crucial for reducing cable joint failure and building a reliable network. It is important to use high-quality products from reputable manufacturers, adhere to industry standards, and consider environmental factors during installation. Regular maintenance and testing can help identify potential issues and prevent failure. Maintaining proper documentation can also be helpful in identifying and preventing future failures.At Compaq International, we offer reliable and long-lasting cable joints, such as heat shrink type, cold shrink type, and premoulded (push on) type, all manufactured in India with the most advanced manufacturing capabilities. We also offer training and guidance to jointers, and now training matters along with grid reliability. Following the steps outlined in this blog can lead to a network that is less prone to cable joint failure and more reliable overall. For more information, write to us at [email protected] or visit us at www.compaqinternational.com.

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

What is Touch-Proof Terminations and why Utilities are Switching to it

What is Touch-Proof Terminations and why Utilities are Switching to it

Mechanical Shear Head Cable Lugs & Connectors

Mechanical Shear Head Cable Lugs & Connectors

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

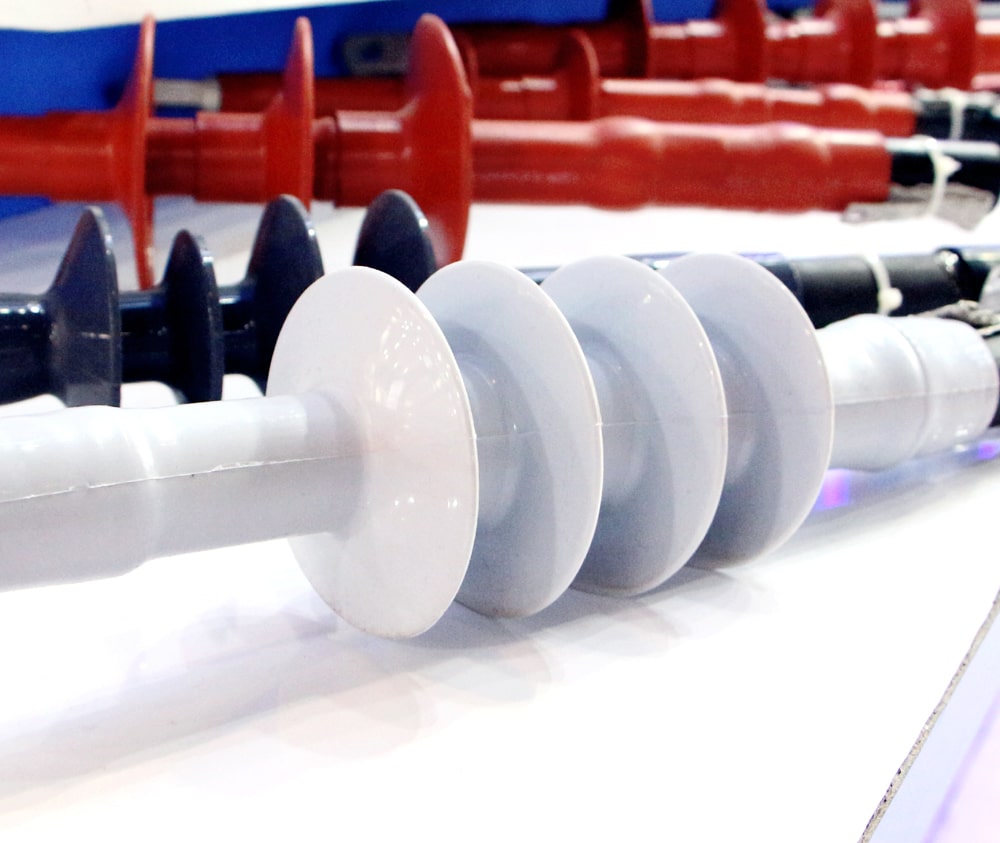

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

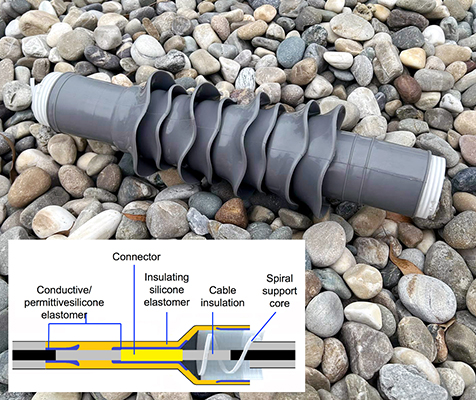

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

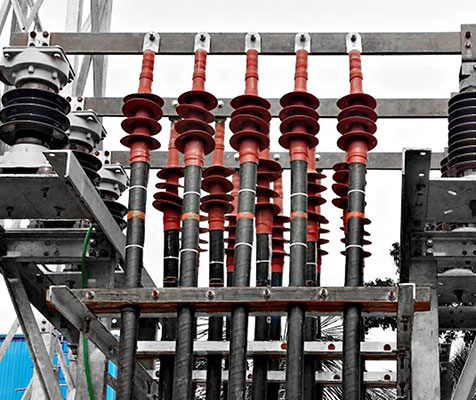

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

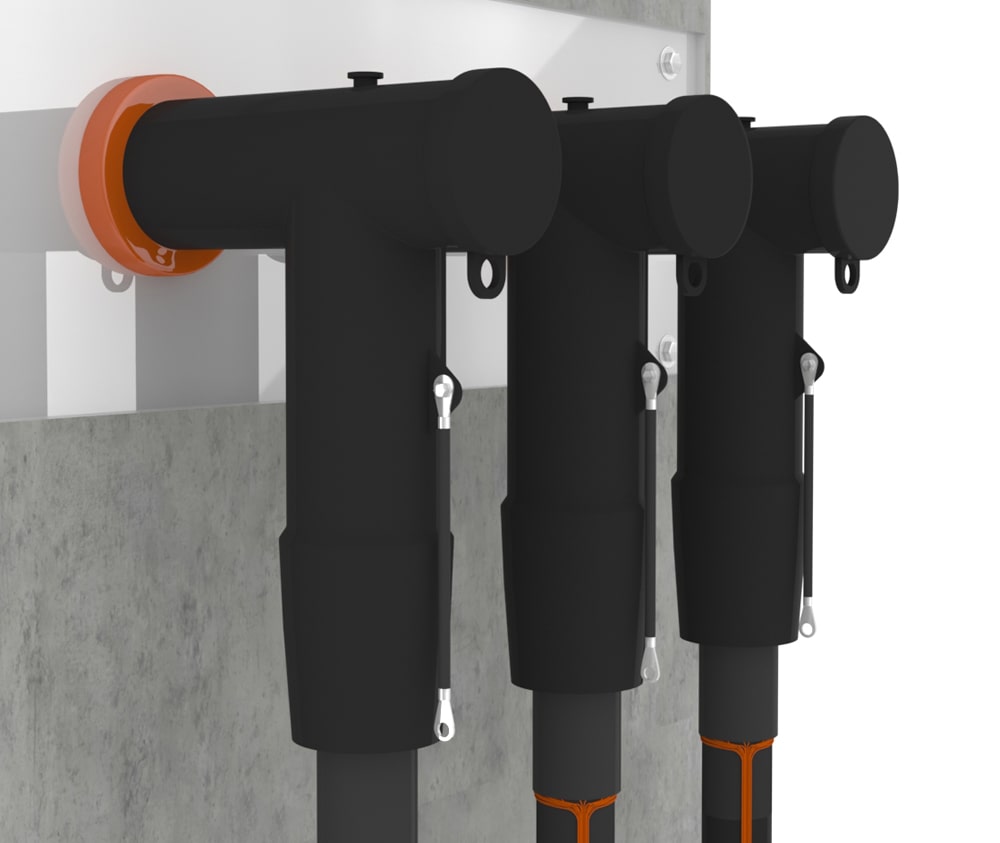

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?