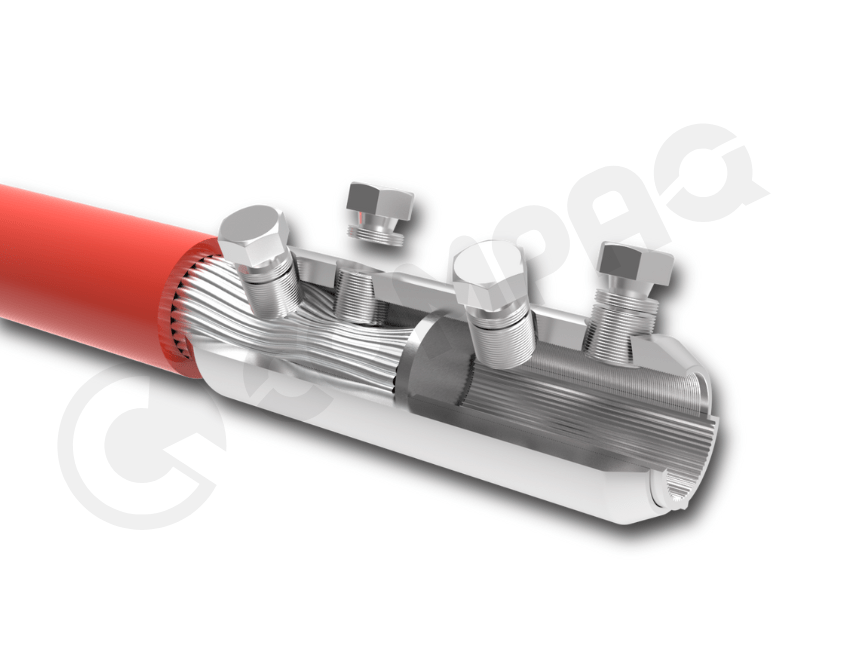

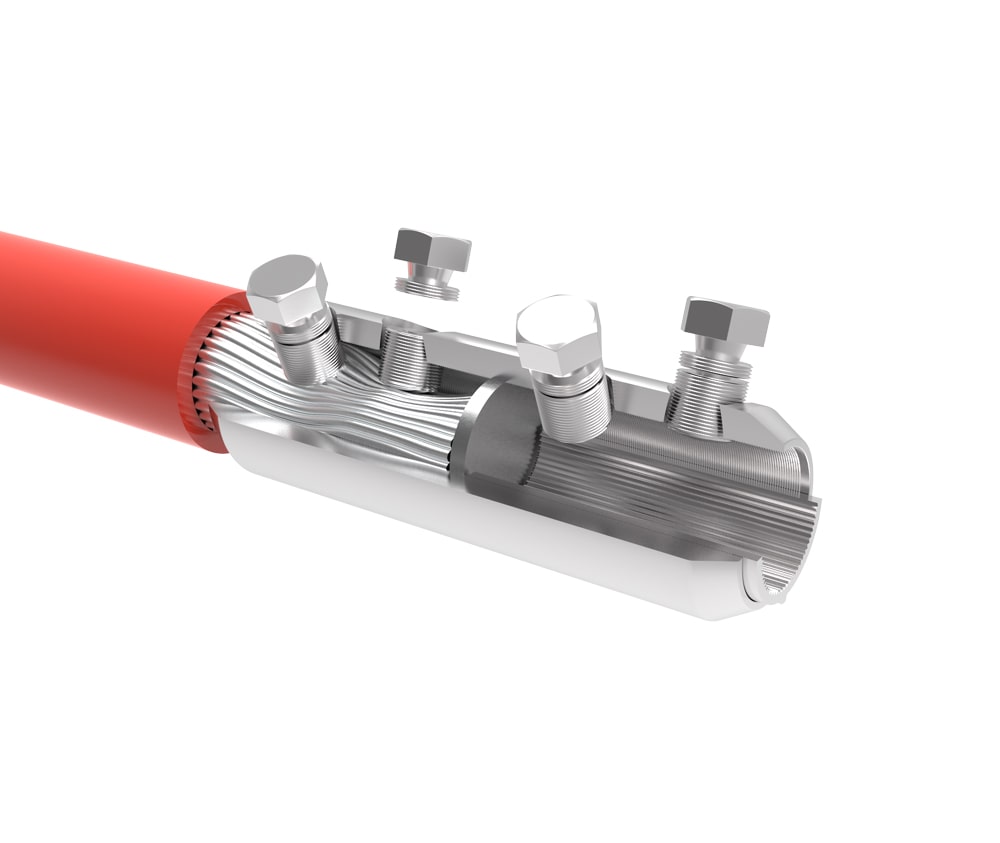

Mechanical Shear Head Cable Lugs & Connectors

How COMPAQ Cable Accessories Support Continuous Power Supply in Life-Dependent Environments

In critical infrastructure such as hospitals, diagnostic centers, and emergency care facilities, uninterrupted electrical power is essential. The integrity of power delivery systems directly influences patient safety, operational continuity, and the functionality of vital equipment. Within this system, cable accessories — including terminations, joints and connectors — play a decisive role.

COMPAQ International provides a complete range of high-reliability cable accessory solutions, engineered to meet the performance and safety standards required in mission-critical installations where failure is not an option.

Field Reliability that Supports Critical Functions

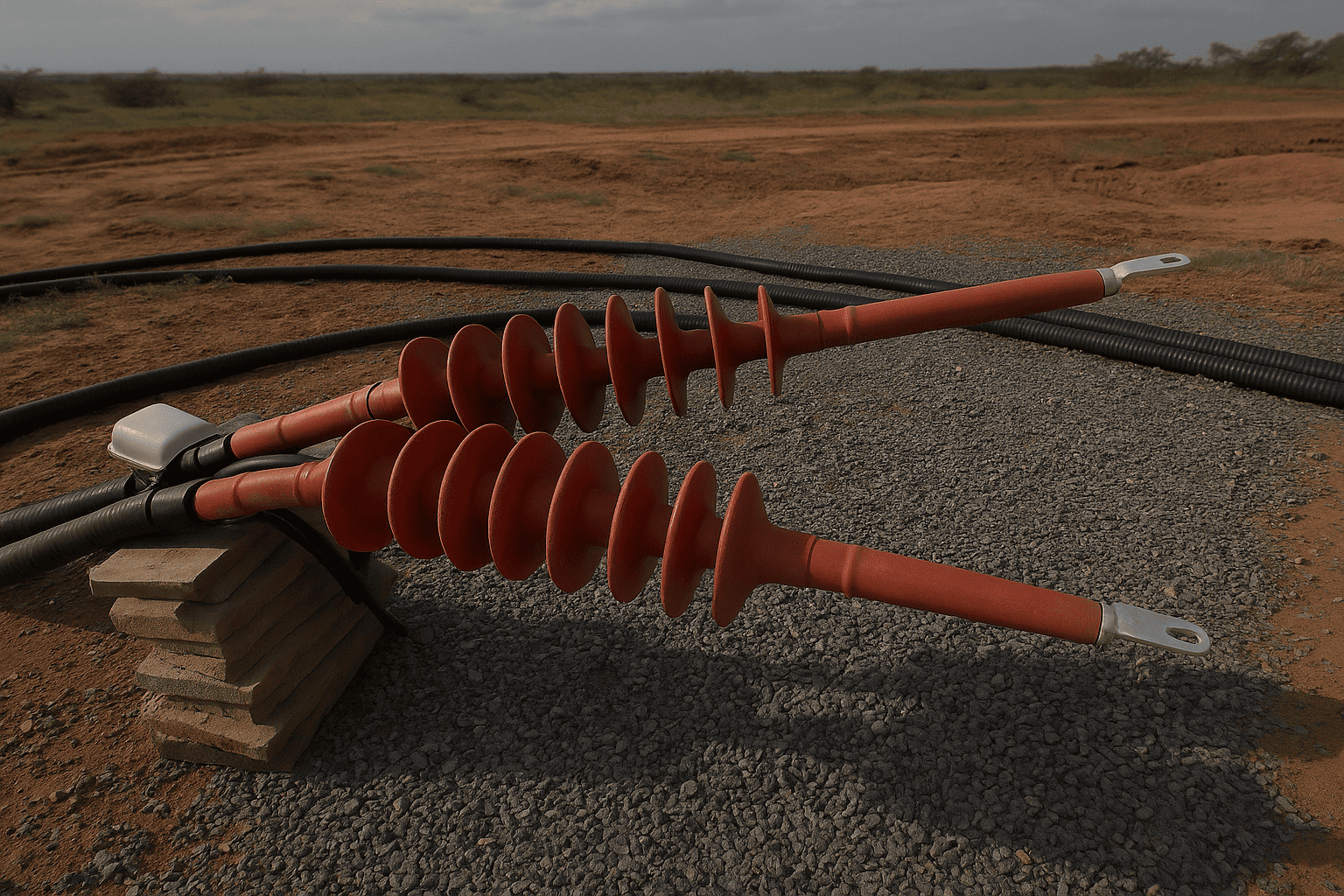

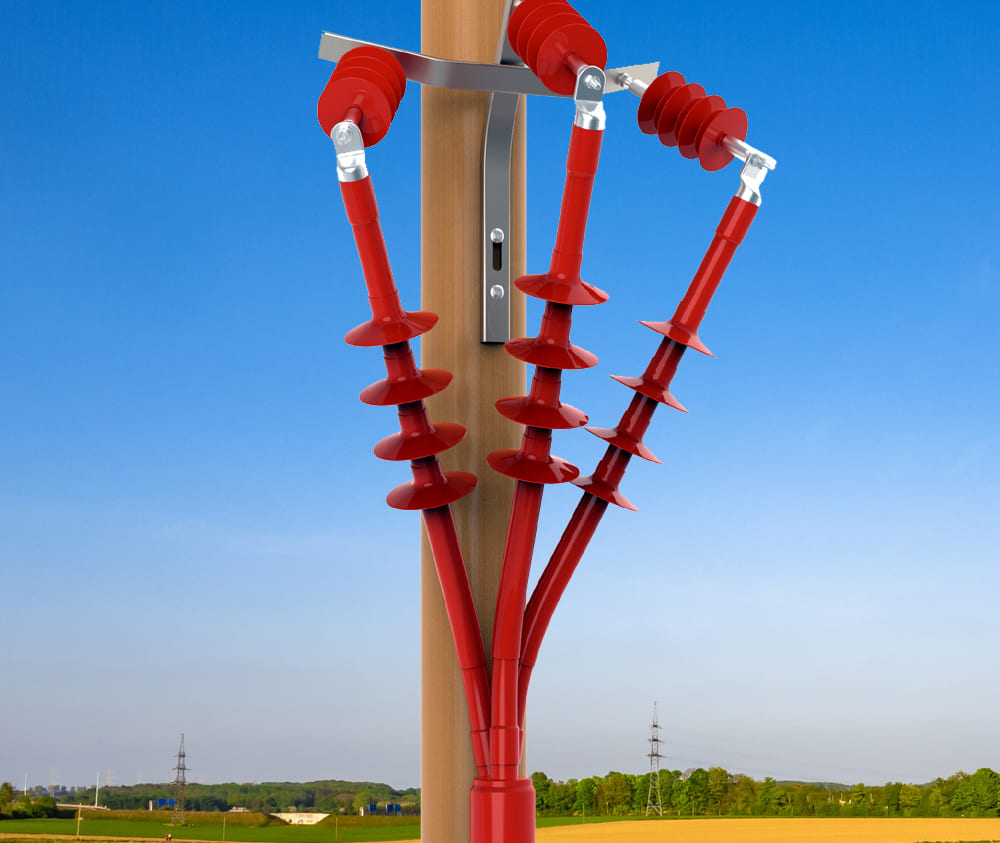

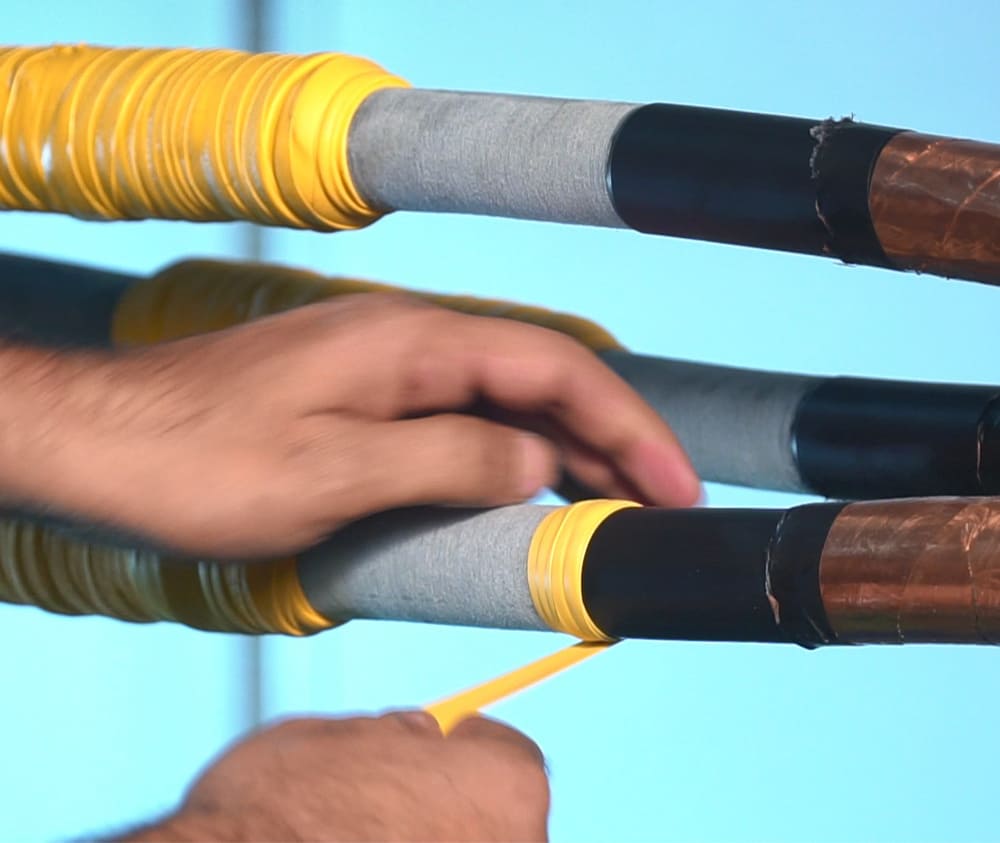

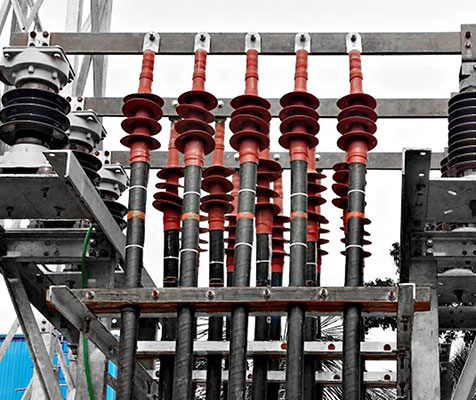

The field installation depicted above, located just 100 meters from a hospital, highlights COMPAQ’s hands-on approach to powering essential healthcare infrastructure. It is here that our heat shrinkable terminations and straight-through joints are being installed as part of a grid extension to support hospital electrical loads.

In such environments, the consequences of product failure are severe. Reliable connections are not just a technical requirement — they are a medical imperative.

Engineered for Life-Sustaining Systems

COMPAQ’s product line is designed and tested for applications where:

- System redundancy and continuous load support are essential

- Power quality and insulation integrity must be maintained under variable loads

- Environmental exposure (humidity, thermal cycles, pollution) challenges long-term performance

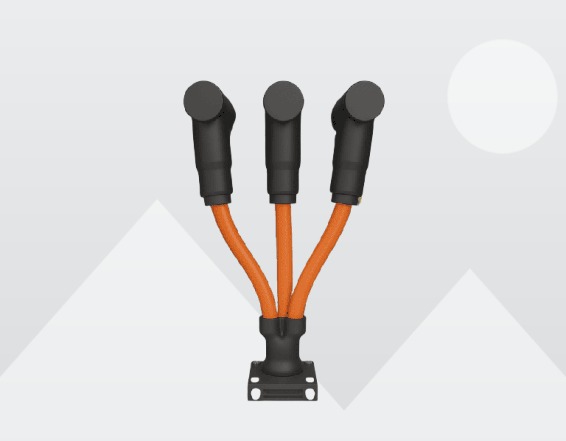

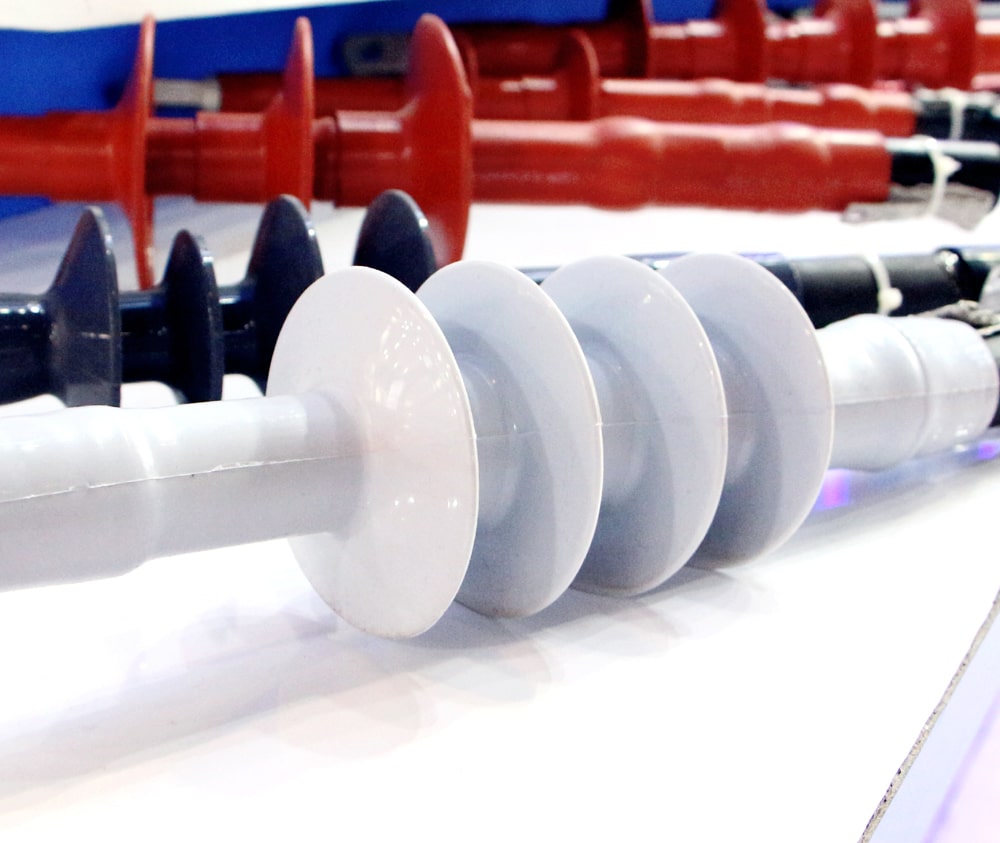

Our 11kV to 66kV Heat Shrinkable Terminations,Joints, and Separable Connectors ensure:

- ✅ Low partial discharge and consistent dielectric strength

- ✅ High tracking and erosion resistance

- ✅ Superior sealing against moisture ingress and contamination

- ✅ Thermal endurance to resist aging over the equipment life cycle

Technical Compliance and Quality Standards

All COMPAQ products are rigorously tested to conform with:

- IEC 60502-4 (Cable accessories for power cables with rated voltages from 6 kV to 30 kV)

- IS 13573 (Indian Standard for heat shrinkable accessories for XLPE cables)

- EN 50181 (for separable connectors for bushings Interface A/C)

Furthermore, our in-house QA process includes:

- Electrical type testing (impulse, AC withstand, PD level)

- Mechanical endurance (pull tests, impact resistance)

- Environmental testing (UV, humidity, salt fog)

Healthcare Applications: Use Case Scenarios

COMPAQ’s cable accessories are deployed in:

- Grid-connected hospital substations

- Backup generator and UPS circuits

- Oxygen plants, ICUs, MRI and CT power lines

- Renewable integration in hospital microgrids

- Temporary mobile care units (disaster recovery zones)

Whether powering a ventilator in a rural district hospital or a full-scale multi-specialty medical facility, COMPAQ ensures long-term electrical safety and operational integrity.

On-Site Technical Support: Installation Assurance

Our involvement does not end with supply. COMPAQ provides:

- Qualified technical personnel for on-site supervision and inspection

- Standardized installation protocols for jointing and termination

- Training to client-appointed contractors and EPC partners

- Troubleshooting and post-installation testing support

This ensures uniform product performance and eliminates installation-related failures.

Dependable Power for Life-Critical Environments

In hospital and healthcare infrastructure, electrical reliability can be the difference between safety and system failure. That is why COMPAQ’s cable accessory systems are engineered not only to perform — but to protect.

When the application is critical, the connection must be COMPAQ.

For Technical Consultations or Project Support:

[email protected], www.compaqinternational.com

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

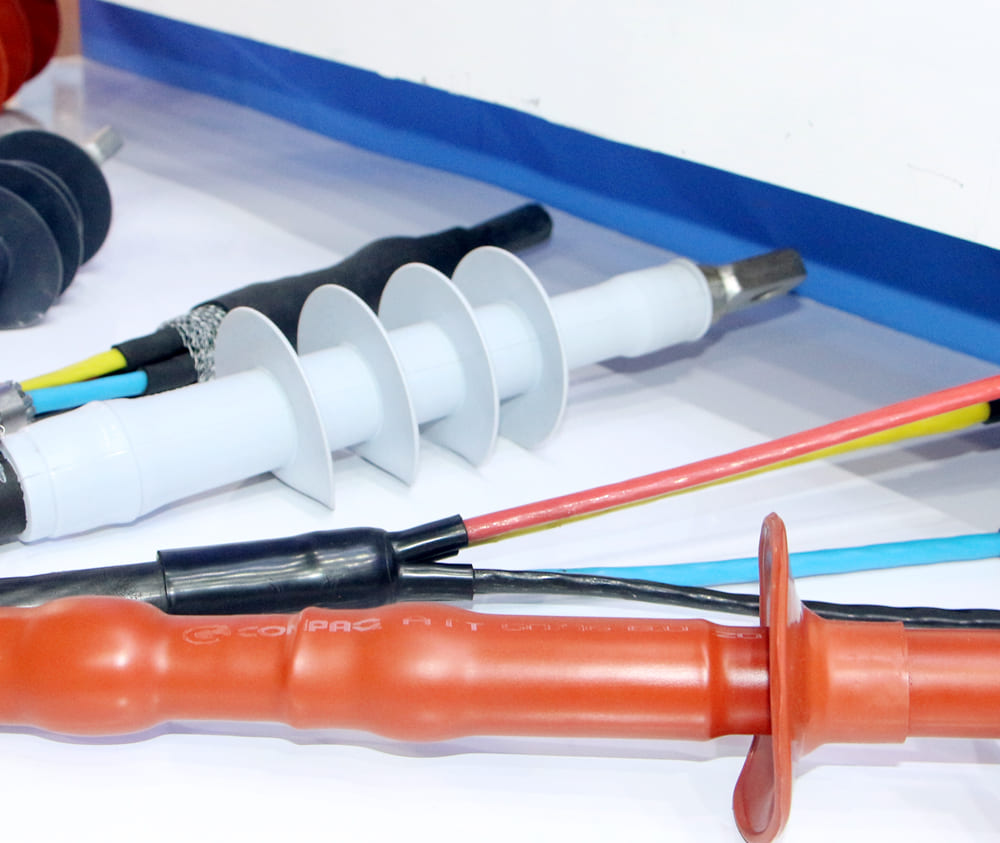

What is Touch-Proof Terminations and why Utilities are Switching to it

What is Touch-Proof Terminations and why Utilities are Switching to it

Mechanical Shear Head Cable Lugs & Connectors

Mechanical Shear Head Cable Lugs & Connectors

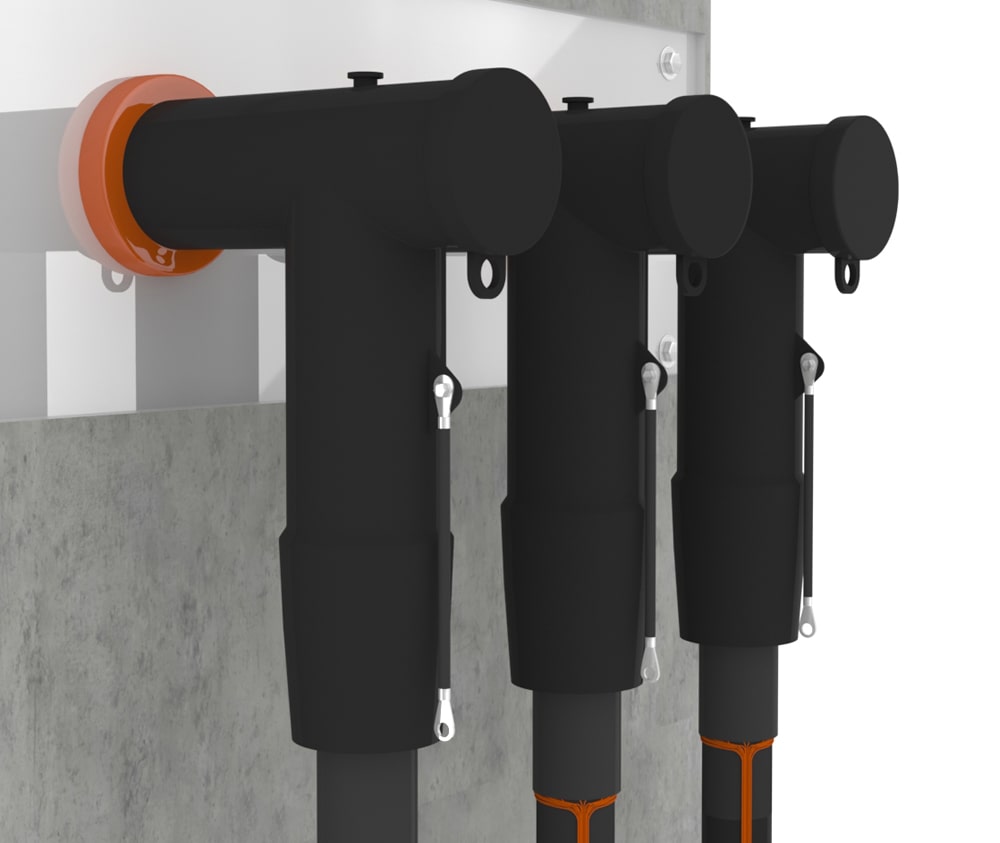

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

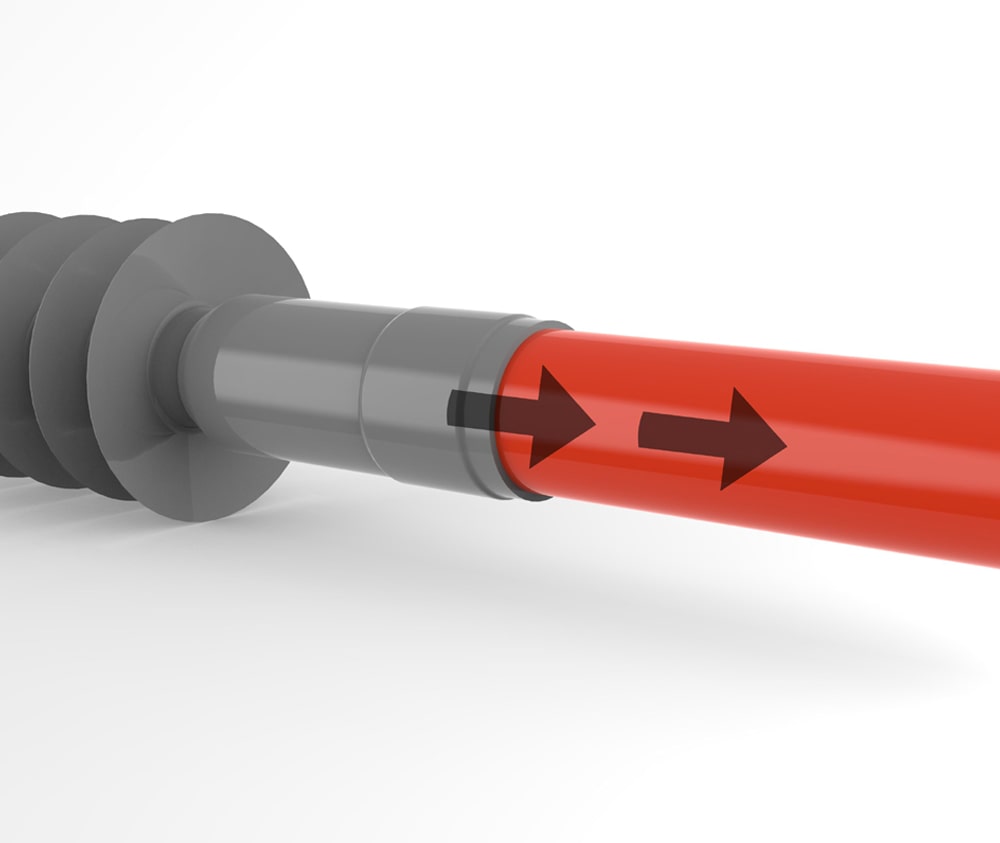

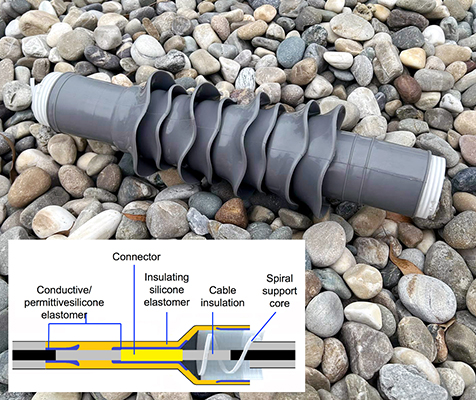

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

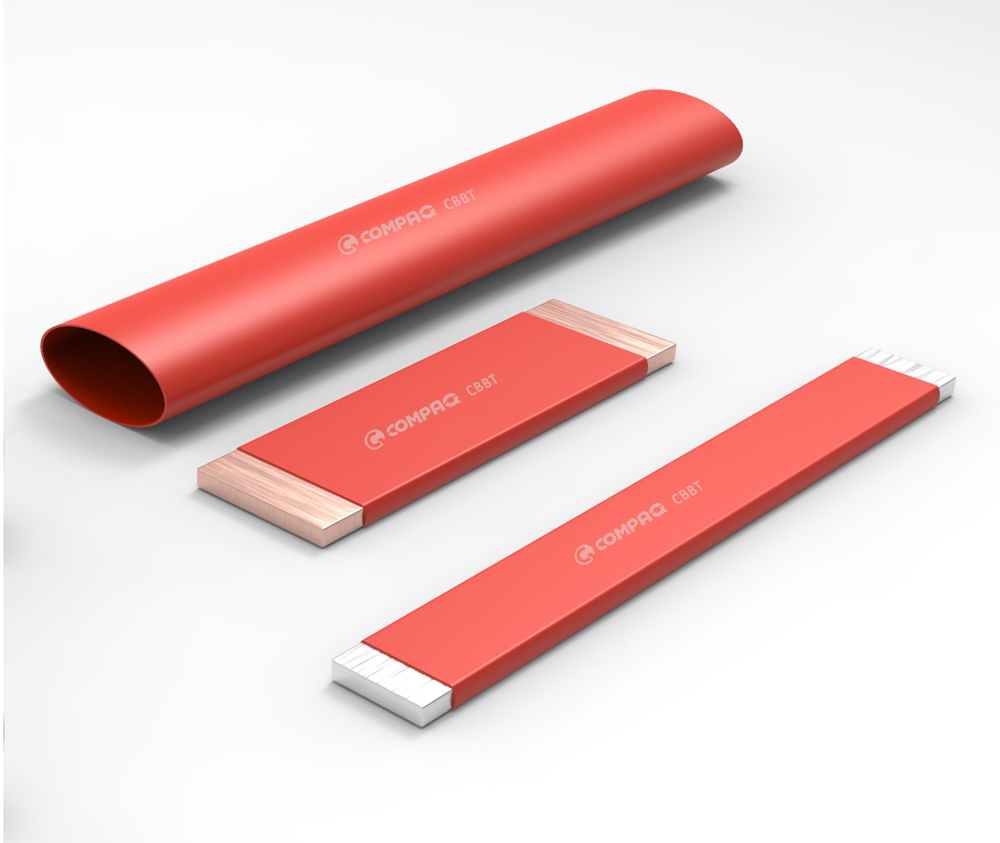

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?