What is Touch-Proof Terminations and why Utilities are Switching to it?

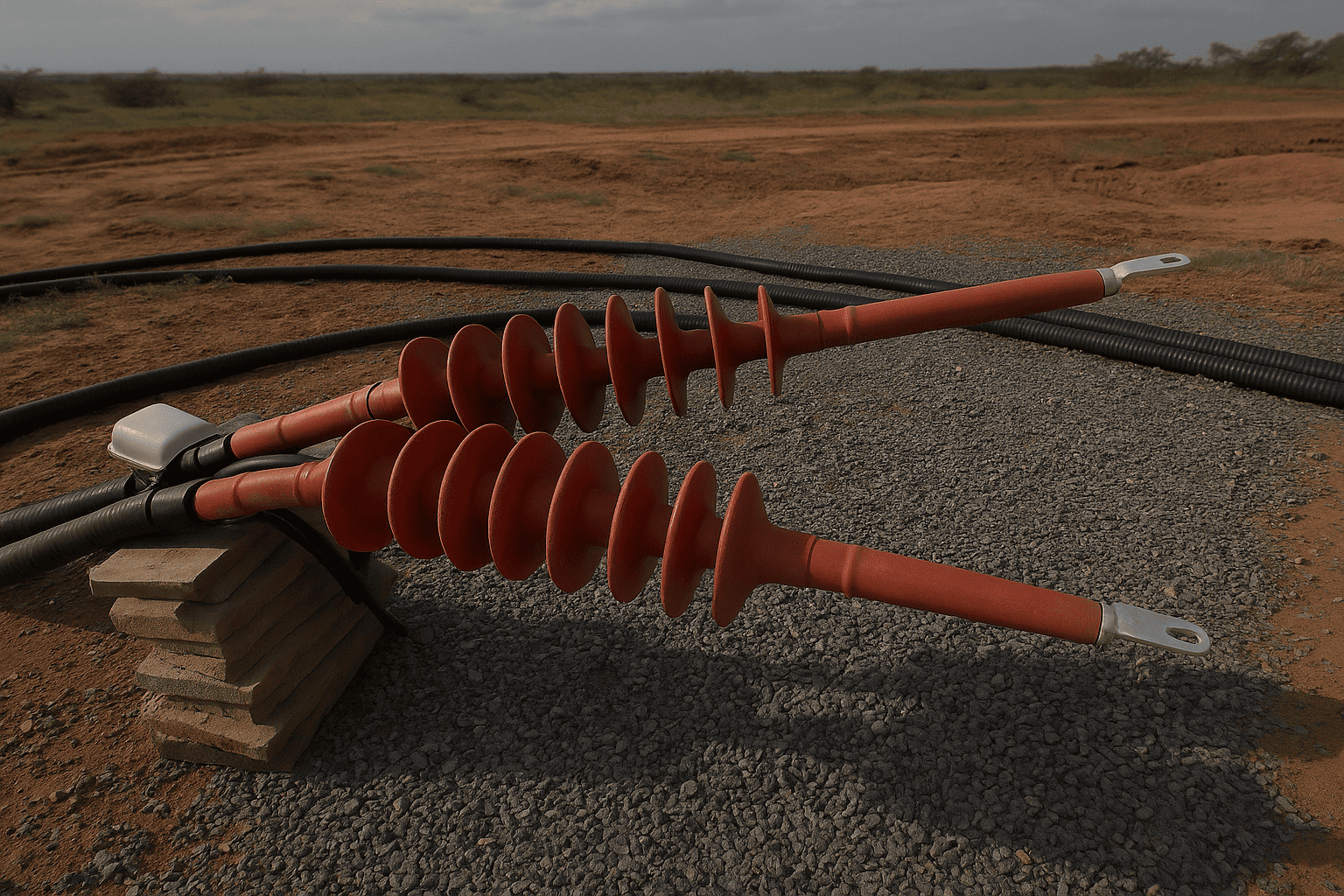

In the evolving landscape of medium-voltage (MV) power distribution, safety, reliability, and modularity are non-negotiable. That’s why utilities and switchgear OEMs across the globe are moving away from traditional open-term systems toward touch-proof terminations, also known as screened separable connectors.

But what exactly does “touch-proof” mean—and why has it become the industry standard?

What Is Touch-Proof Termination?

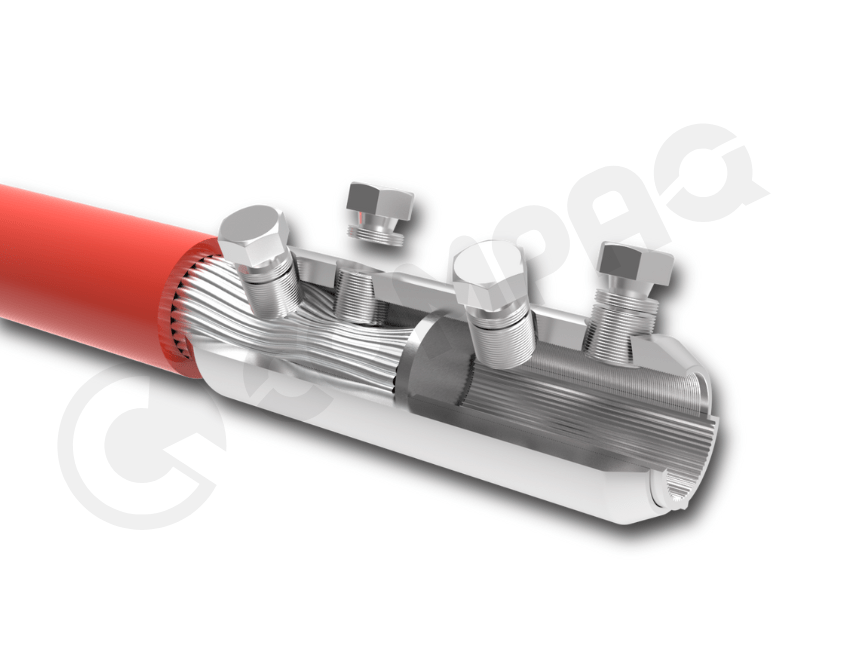

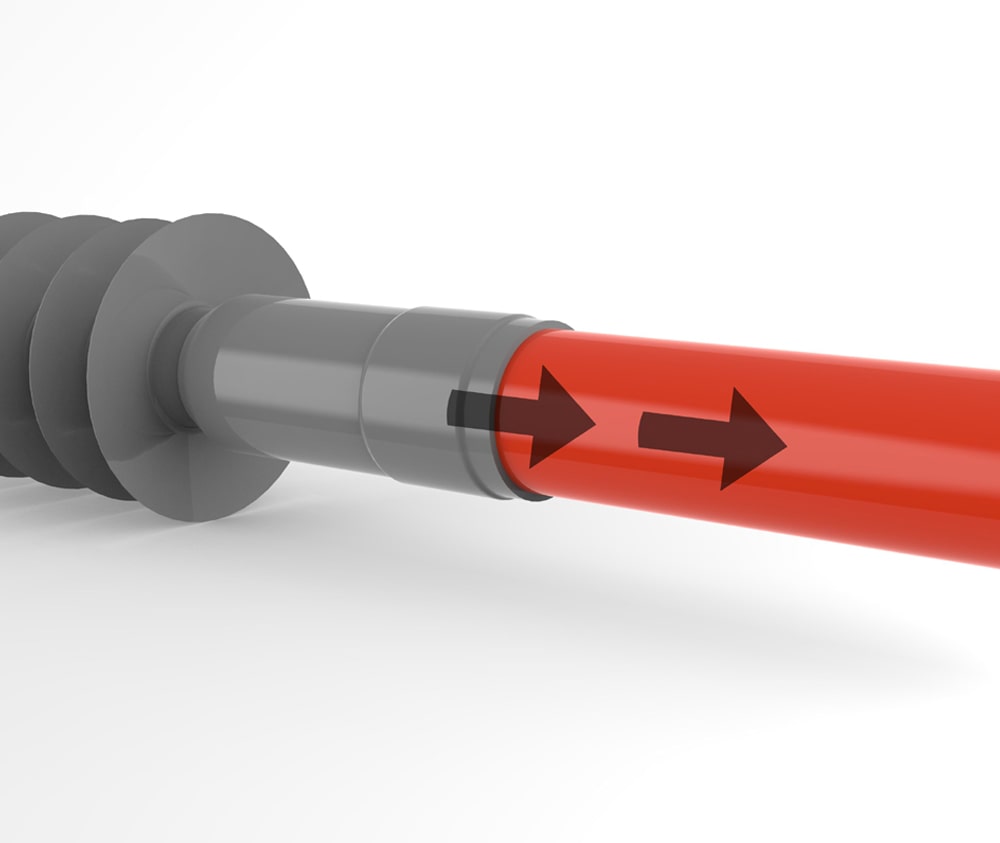

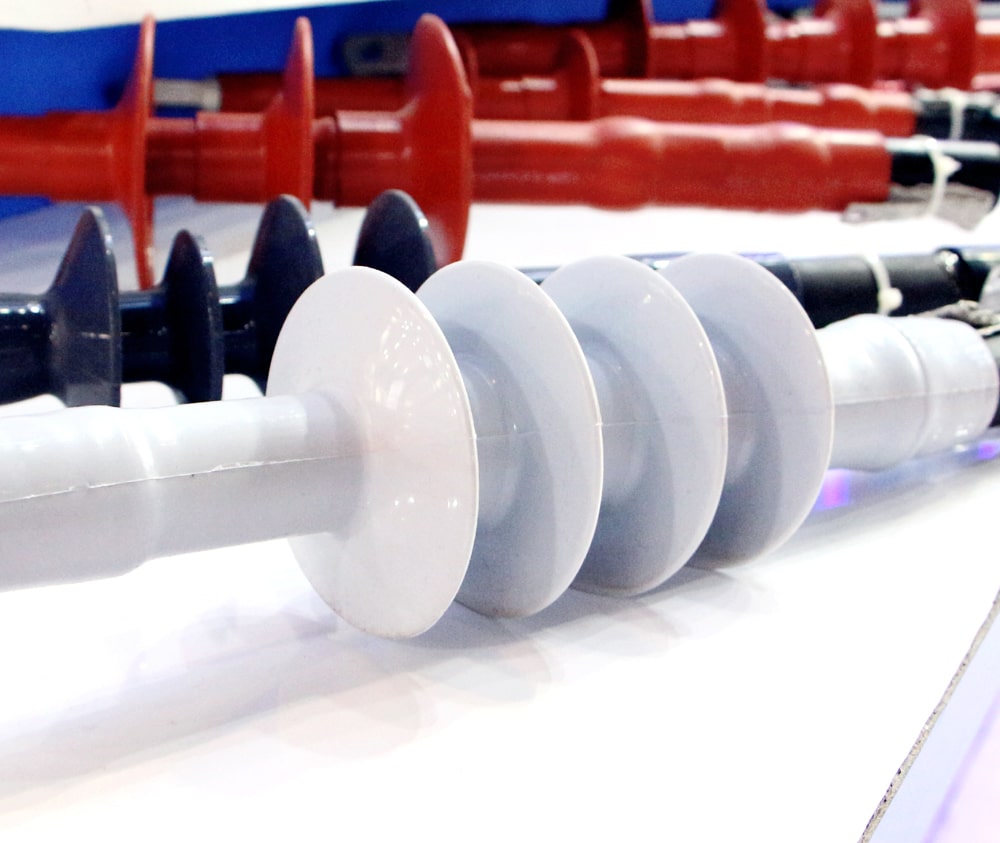

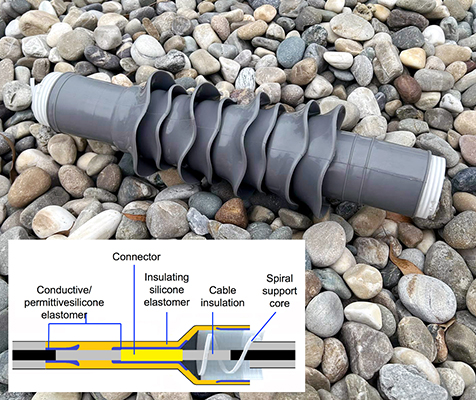

A touch-proof termination refers to a fully enclosed, screened, and insulated connection system that prevents accidental contact with live conductive parts. These terminations are most commonly molded from high-performance EPDM or silicone rubber and feature an externally conductive screen that’s earthed—ensuring the surface remains at ground potential even under full operating voltage.

In simple terms: even when energized, the outer body of a touch-proof connector is safe to touch, eliminating the risk of electric shock.

Key Features of Touch-Proof Terminations

- Fully insulated and screened: Ensures complete operator safety during energization.

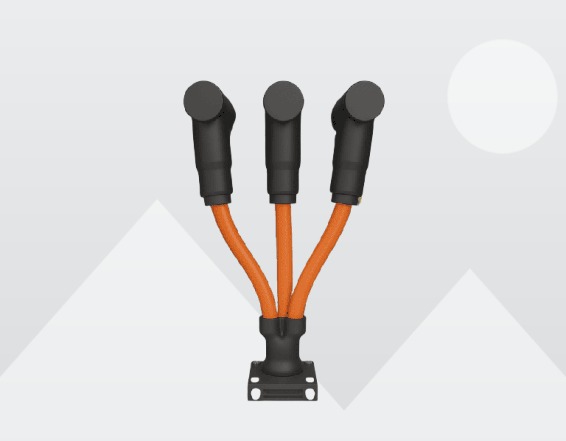

- Compact, elbow-shaped design: Ideal for confined switchgear and RMU chambers.

- Separable and modular: Enables easy installation, testing, and replacement.

- Submersible construction: Suitable for outdoor, wet, or underground environments.

- Compatible with EN 50181 bushings (Type C): Supports 630A, 800A, and 1250A systems.

The Problem with Conventional Terminations

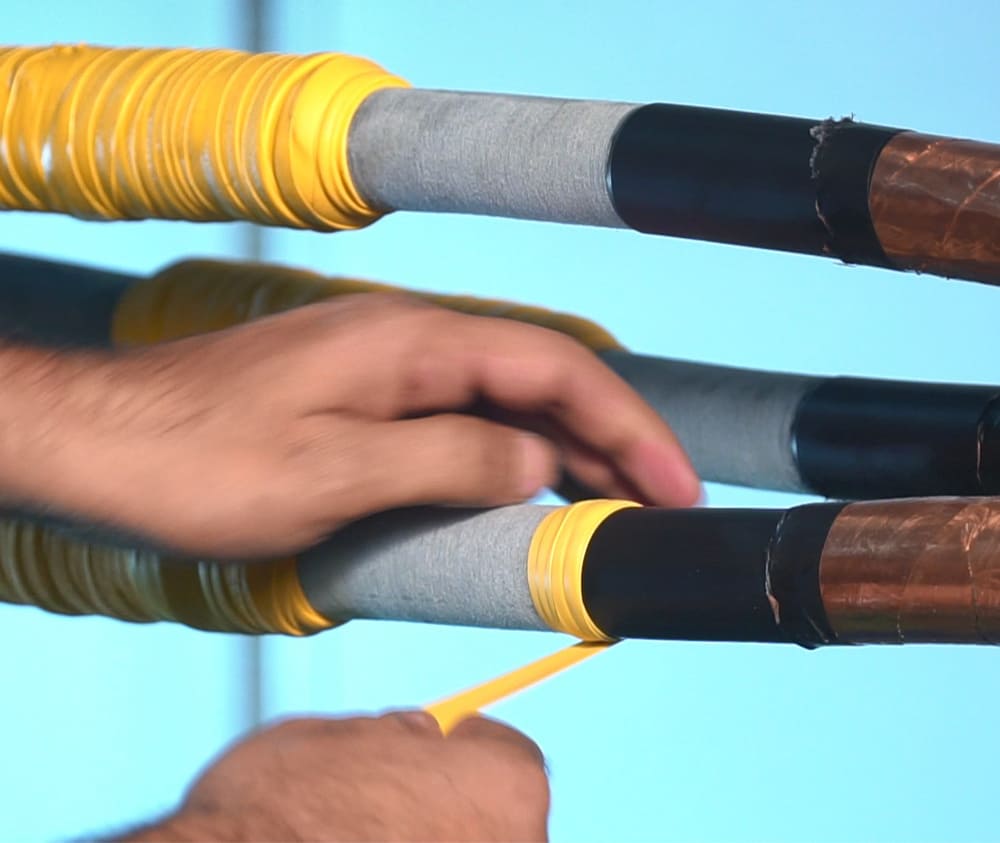

- Traditional heat shrink or cold shrink terminations, while reliable, are: Exposed to air, water, and mechanical damage.

- Non-touch safe, requiring clearances and additional shielding.

- Harder to maintain or replace without full shutdowns.

Why Utilities Are Switching

- Safety First

Touch-proof terminations eliminate exposure to live parts, allowing technicians to safely work around energized equipment—critical for grid uptime and worker protection. - Space Optimization

Their compact design reduces the footprint required inside GIS panels or RMUs, enabling more compact and modular substations. - Interchangeability

Standardized dimensions (EN 50181) make touch-proof terminations vendor-agnostic— a major advantage in procurement flexibility. - Reduced Downtime

Since the terminations are separable, they allow hot-swapping of connectors, surge arresters, or T-junctions without dismantling the entire system. - Ease of Testing

Test points integrated into the elbow body allow voltage presence detection, diagnostics, and partial discharge monitoring—without disconnection.

Use Cases and Growth

Today, touch-proof terminations are becoming the preferred standard in:

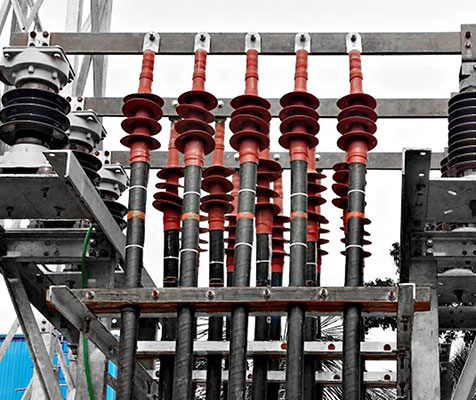

- GIS and RMU connections (up to 36kV)

- Solar and wind power evacuation

- Containerized substations

- Compact metro & airport substations

- Oil & gas installations with safety-critical ratings

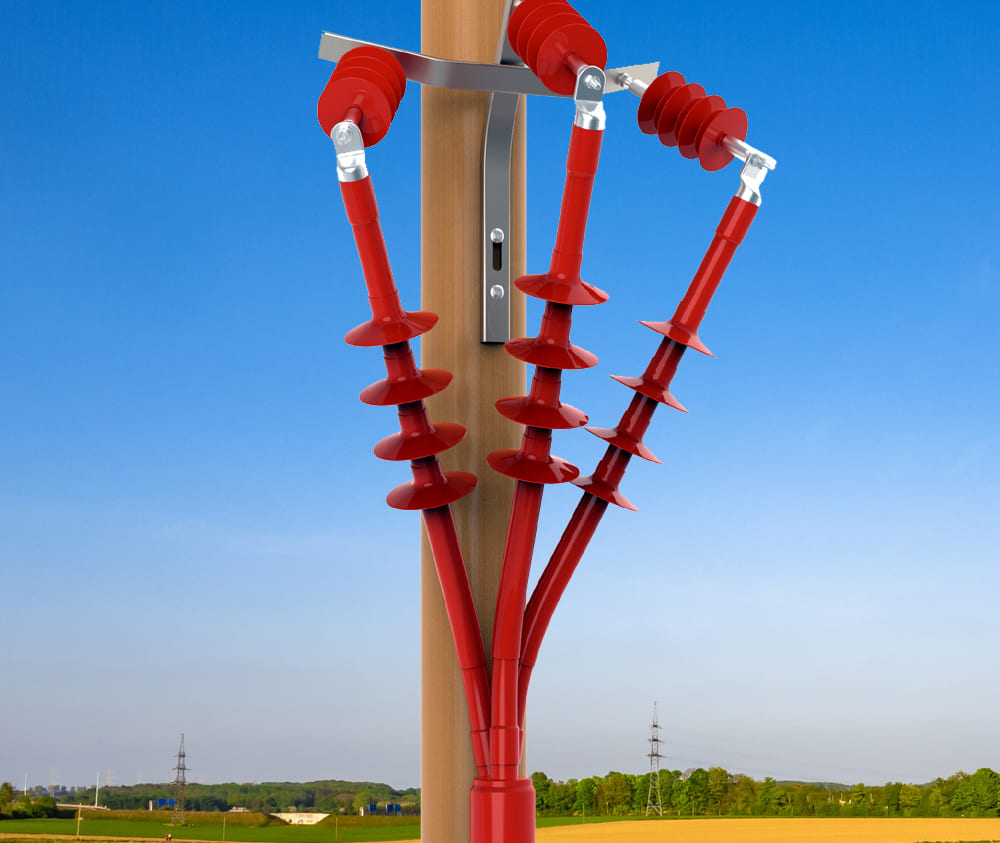

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

Safe & Durable 66kV Heat Shrink Terminations by COMPAQ – Ensuring High Voltage Reliability in the Field

What is Touch-Proof Terminations and why Utilities are Switching to it

What is Touch-Proof Terminations and why Utilities are Switching to it

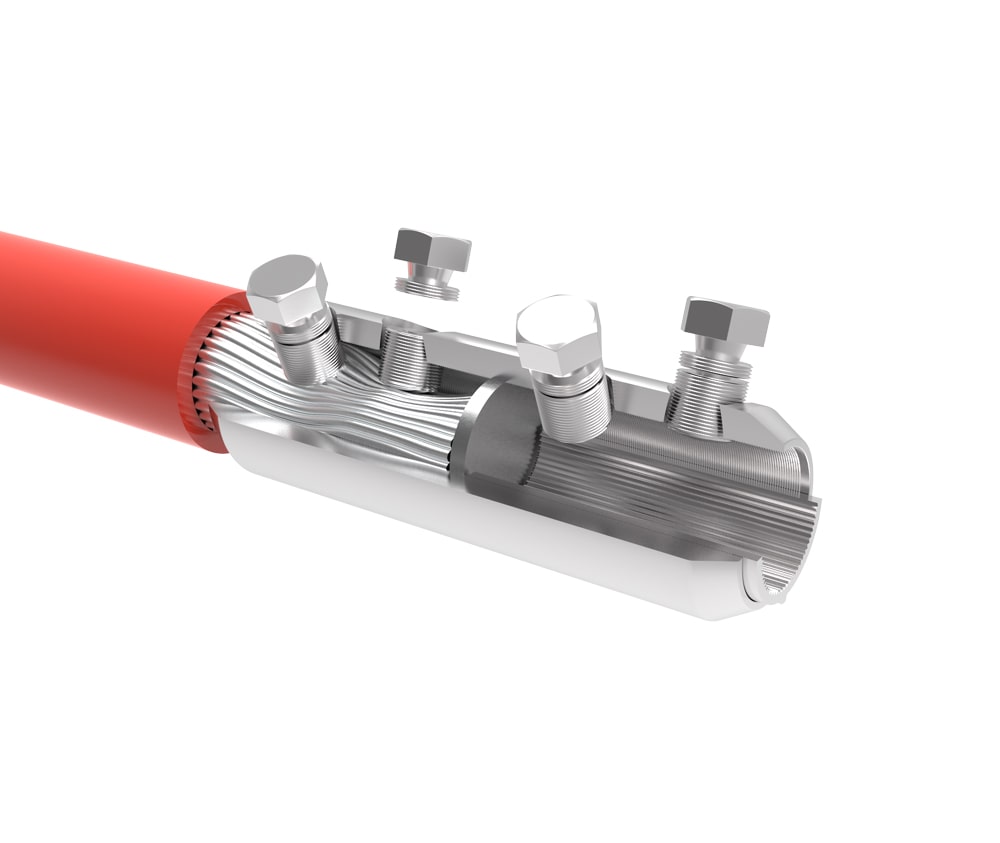

Mechanical Shear Head Cable Lugs & Connectors

Mechanical Shear Head Cable Lugs & Connectors

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

COMPAQ Elbow Terminal Protector (CRTP 1224) - Ensuring Safe and Reliable Cable Termination

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

What are Pre-moulded Slip-On or Push-On Cable Joints? A Technical Insight

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

A Complete Guide to Heat Shrink Cable Joints: Reliable and Durable Connectivity

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Mechanical Shear Head Cable Lugs and Connectors: Revolutionizing Cable Connection Technology

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

Understanding Cold Shrink Cable Joints: A Modern Solution for Reliable Connectivity

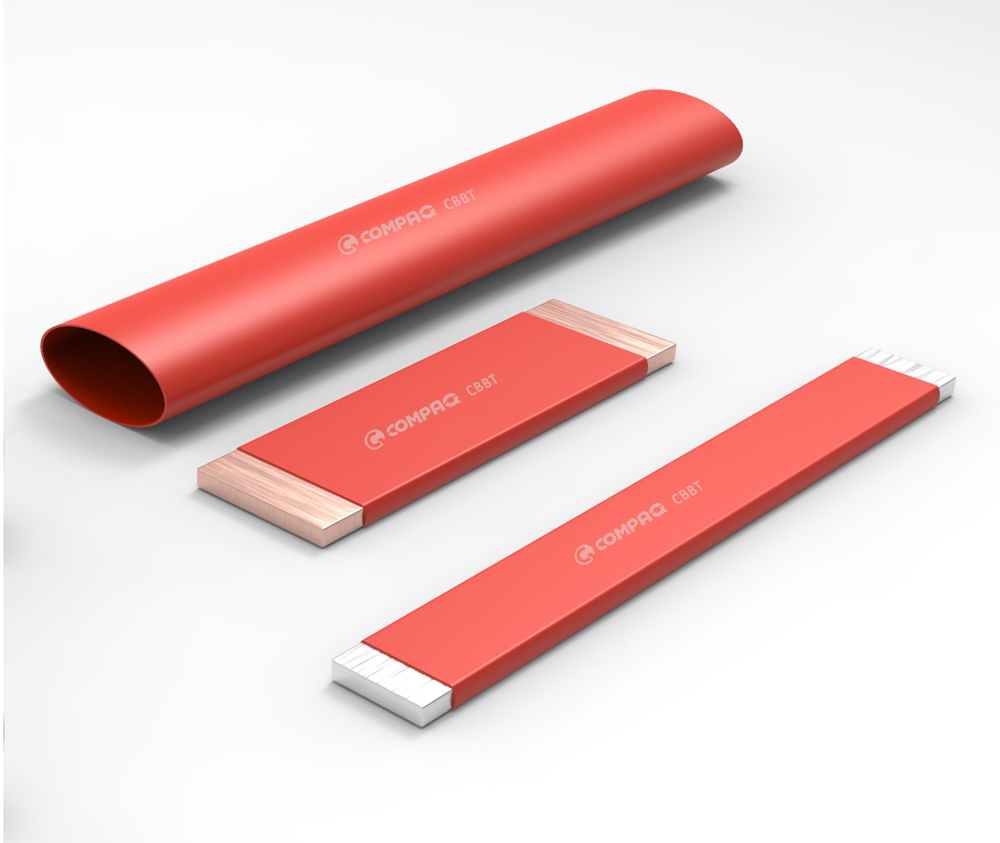

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

COMPAQ Busbar Insulation Tubing: A Compact Solution for Enhanced Electrical Safety

Beyond Accessories: Building Reliable Connections with COMPAQ International

Beyond Accessories: Building Reliable Connections with COMPAQ International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Strengthen Your Busbar Protection: Heat Shrinkable Insulation Tubing from Compaq International

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Ever Wonder How Heat Shrink Tubes Remember Their Smaller Size?

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Understanding Medium Voltage Cable Terminations: A Comprehensive Guide

Your Trusted Partner in MV Cable Terminations

Your Trusted Partner in MV Cable Terminations

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

The Easy Way to Connect and Protect Medium Voltage Cables with COMPAQ Pre-Moulded Joints

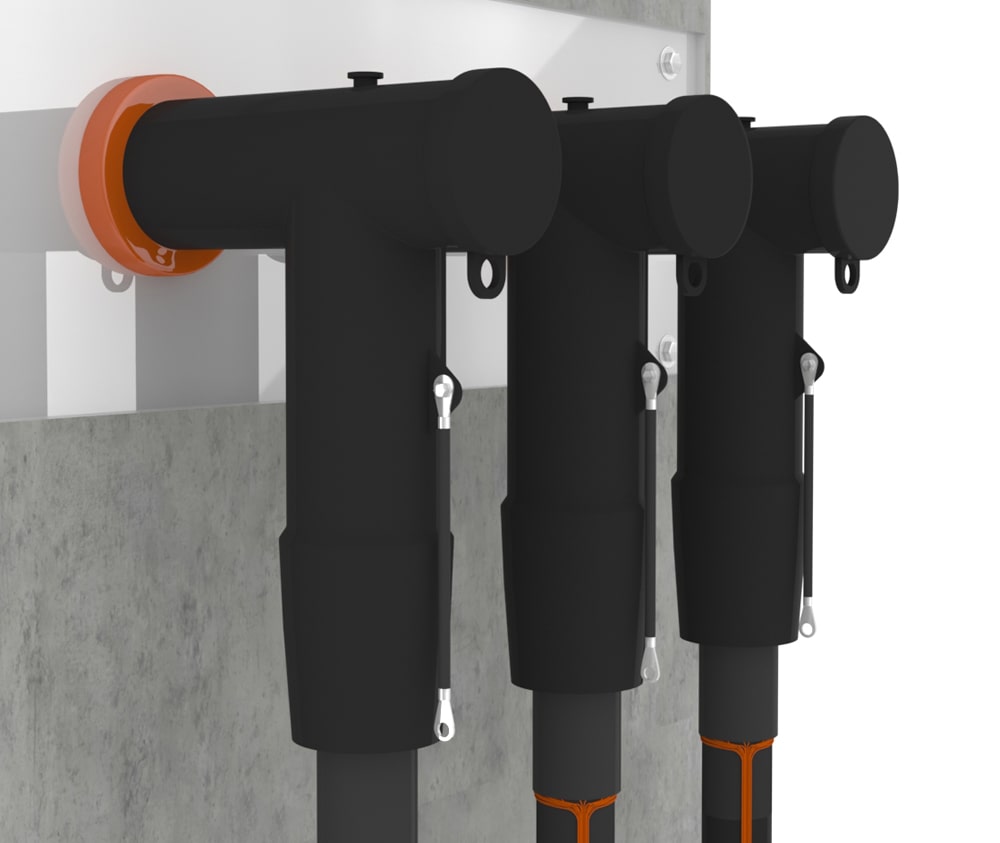

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Compaq International's Screened Separable Connector — Touch-Proof Terminations Up to 36 kV

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Are you in search of a robust solution to safeguard your cables from tracking and erosion?

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

Why Choose Compaq International? A Tale of Quality, Innovation, and Trust

How to Reduce Cable Joint Failure and Build a Reliable Network?

How to Reduce Cable Joint Failure and Build a Reliable Network?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Enhancing Energy Connections: Discover the Power of Cable Joints or you can say What are Cable Joints?

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Do you need reliable insulation and cable crutch protection for Low voltage cable terminations

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Exploring Compaq International’s Mechanical Shear Head Bolt Repair Connectors

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Compaq CSCM Stress Control Mastic Tape: A Safe and Reliable Solution for Electrical Stress Relief

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Get Plugged-In with COMPAQ Medium Voltage Separable Connectors- Enjoy Maximum Efficiency with Our Separable Connectors

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Understanding the Basics of COMPAQ Pre-Moulded (Slip-On) Cable Joints and their Benefits

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Everything you need to know about COMPAQ Heat Shrinkable Heavy Wall Tubing

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Have you ever wondered how switchgear and transformer cable boxes are able to

operate safely in environments with limited air clearances

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

Compaq Heat Shrink Cable End Caps: The Ultimate Cable Protection

The Role of Medium Voltage Cable Accessories in Modern Life

The Role of Medium Voltage Cable Accessories in Modern Life

Welcome to the world of Heat Shrink Technology!

Welcome to the world of Heat Shrink Technology!

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

Are You Looking For An Effective Way To Insulate And Protect Your Substation And Switchgear Up To 66 kV?

What are Cable Joints?

What are Cable Joints?

What are Separable Connectors?

What are Separable Connectors?

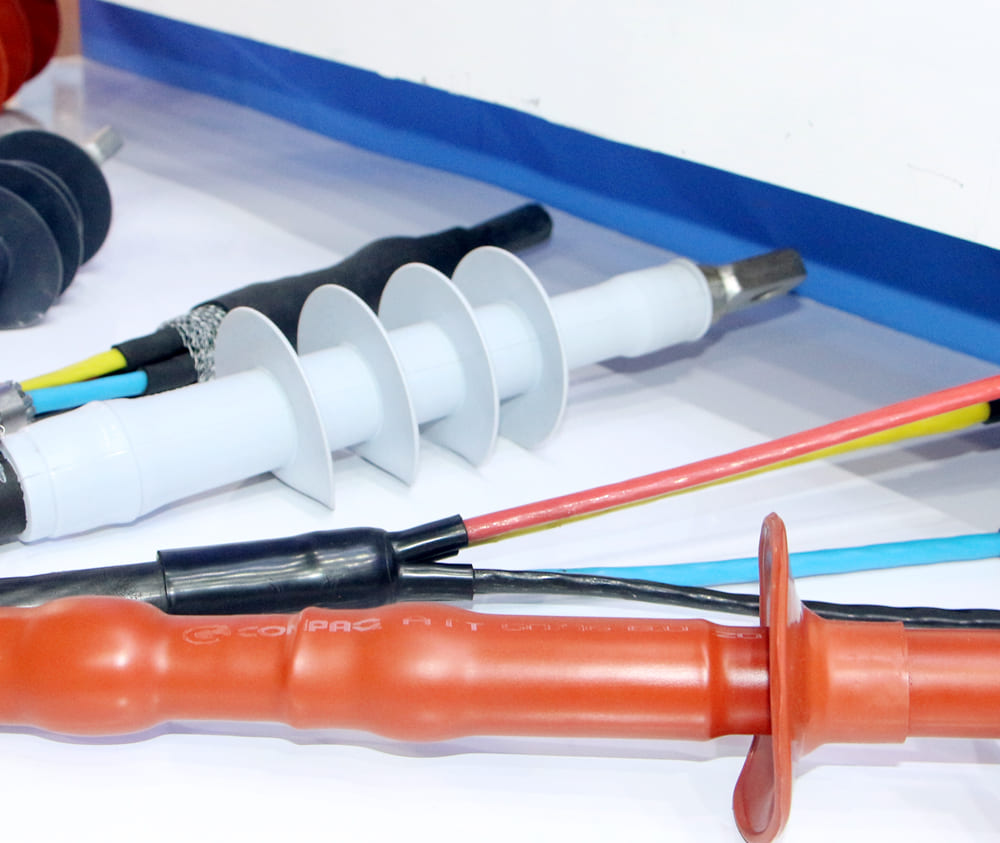

What are Heat Shrink Cable Terminations

What are Heat Shrink Cable Terminations

What are Cold Shrink Cable Terminators?

What are Cold Shrink Cable Terminators?

What are Cable Terminators?

What are Cable Terminators?

What are Underground Cabling Systems?

What are Underground Cabling Systems?

What are Heat and Cold Shrink Technologies?

What are Heat and Cold Shrink Technologies?

What is Cold Shrink Technology?

What is Cold Shrink Technology?